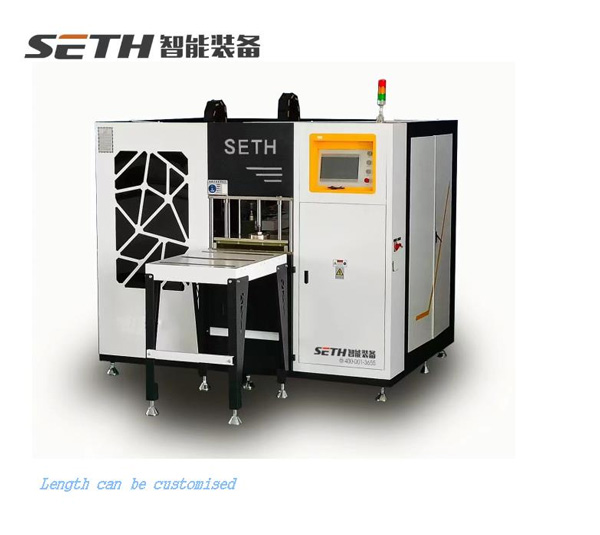

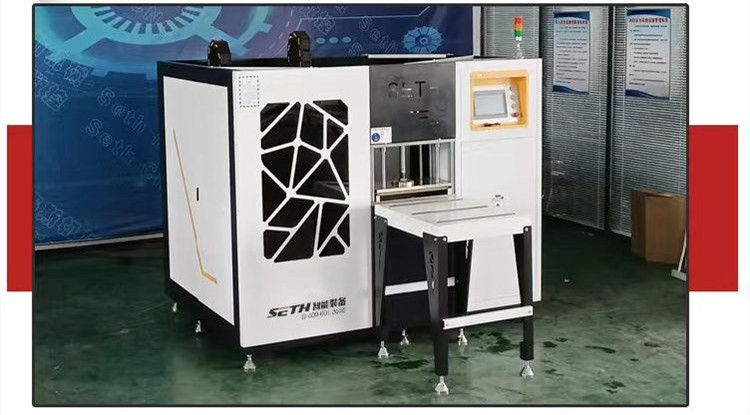

Aluminum Profile Five-axis CNC End Milling Machine

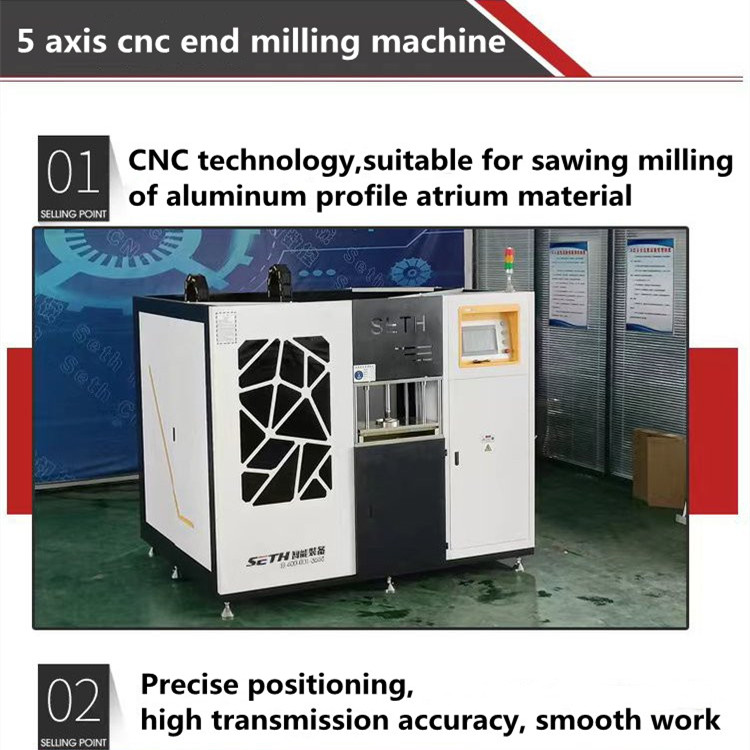

Aluminum Profile Five-axis CNC End Milling Machine is suitable for sawing and milling of the end face tenon and step surface in the doors and Windows. It is controlled by the 5-axis numerical control system.

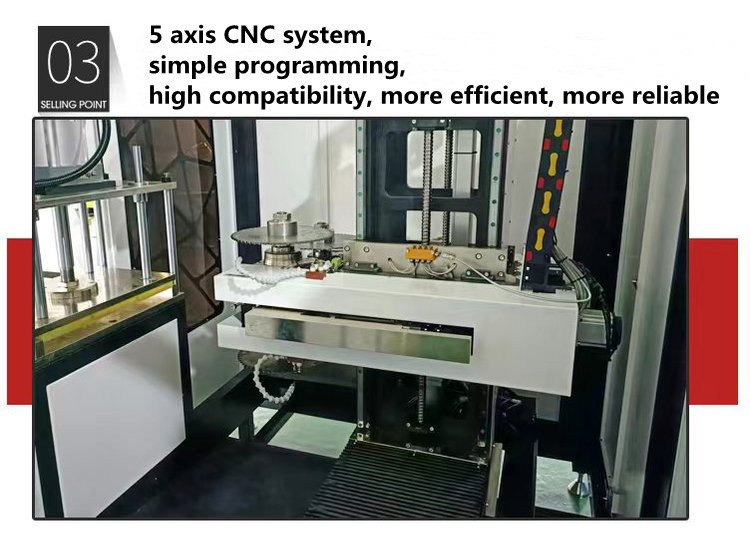

It is easy to program, high compatibility, more efficient and more reliable.

The 5-axis CNC end milling machine for aluminum doors and windows is a cutting-edge piece of equipment. It allows for precise and efficient milling of the end faces of aluminum profiles, resulting in high-quality finished products. With its advanced computer numerical control technology, this machine is capable of performing complex milling operations with ease. Its 5-axis configuration enables it to work on profiles from all angles, providing unprecedented accuracy and flexibility. This machine is a must-have for any manufacturer looking to streamline their production process and improve their product quality.

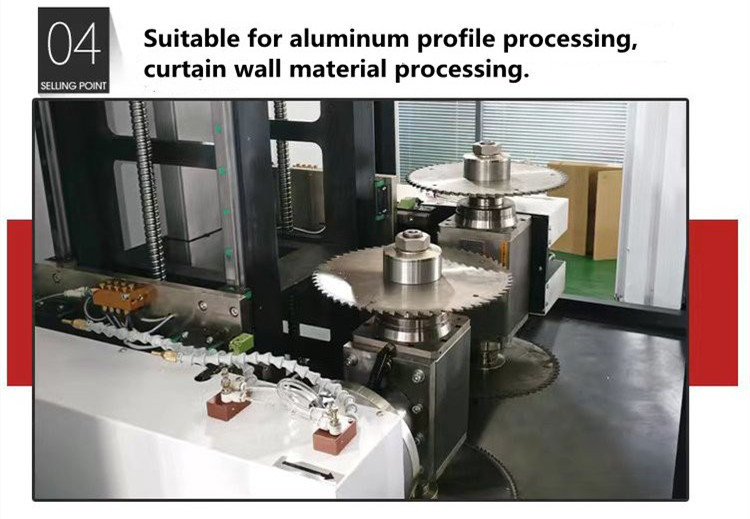

1. Two sawing and milling motors are installed, one realizes horizontal milling and the other realizes vertical slitting, giving consideration to the end milling operation of various sections and strengthening the middle of the profile, which is more universal.

2. Vertical slitting saw blade Angle adjustable, wider range of application.

3. Two milling motors by five axis CNC servo control, no manual adjustment, can be quickly and easily through the selection of preset procedures to complete the processing, can be continuous processing of different sections of the profile.

4.Adopt precision rack and pinion feed, more stable.

Power source | 380v 50Hz |

Total motor power | 10kw |

Motor speed | 2800r/min |

Working pressure | 0.6 ~ 0.8MPa |

Milling cutter diameter | ø250mm×ø32mm |

Saw blade size | ø300mm×ø350mm |

X axis adjustment stroke | 0 ~ 400mm |

Y-axis adjustment stroke | 0 ~ 200mm |

Z axis adjustment stroke | 0 ~ 200 mm |

Dimensions | 2500 mm×1700mm×2000mm |

Weight | 1000KG |

Related Products

Submitted successfully

We will contact you as soon as possible