End Milling Machine For Aluminum Profile

End milling machine for aluminum profile

1.It is suitable for milling the end face of aluminum profile, so as to meet the matching between center stile and frame material.

It can mill multiple profiles at one time with high efficiency.

2.Three-axis two motors can simultaneously carry 4- 6 cutters.

3.Cutting tools can be adjusted up and down and left and right to adapt to machining with different shapes and sizes.

4.The cutting tool is adjustable, and it is unnecessary to customize the cutting tool when processing different profiles,

thus shortening the production preparation, cycle and reducing the cost.

5.The motor phase sequence protector is installed in the circuit system, which improves the safety of the system.

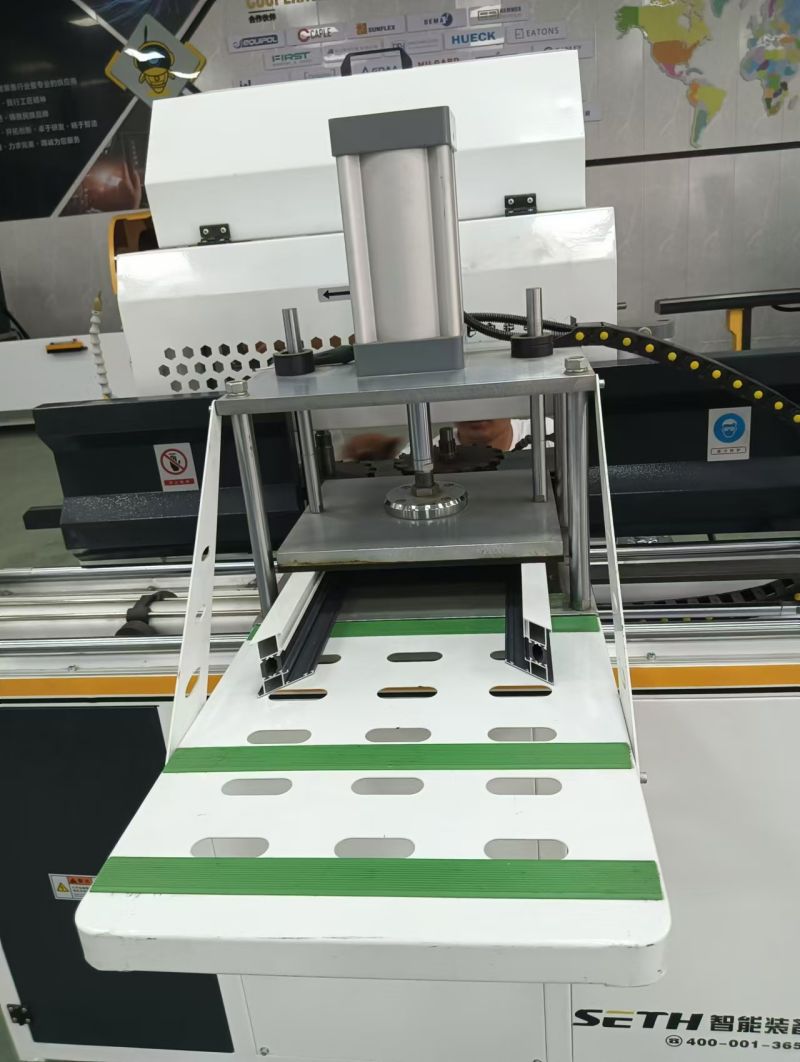

6.Gas-liquid damping device is adopted in the working progress system, which is stable and reliable

End milling machine for aluminum window profile

Featrure:

(1)Milling the aluminum mullion profile to connect the mullion profile and frame profile.

(2)Can mill many profile in one time with high productivity.

(3)Milling Knives can be adjusted up/down and left/right to meet different type of profile.

(4)Milling knives are adjustable for milling different profile, without special made knives

(5)Large diameter of milling knives, high speed milling, good quality milling profile surface.

(6)Adopted the electrical motor protect device to improve the safety.

| Power supply | 380V/50Hz |

| Total motor power | 4.4kW |

| Motor speed | 2800r/min |

| Operating pressure | 0.6~0.8MPa |

| Motor shaft diameter | Ф32mm |

| Milling cutter diameter | Ф250mm |

| Worktable feed stroke | 0~1360mm |

| Open tenon | 40mm |

| Worktable dimension | 330×320mm |

| Motor adjustment stroke | 0~85mm |

| Overall dimension | 2240×1020×1670mm |

| Weight | 450kg |

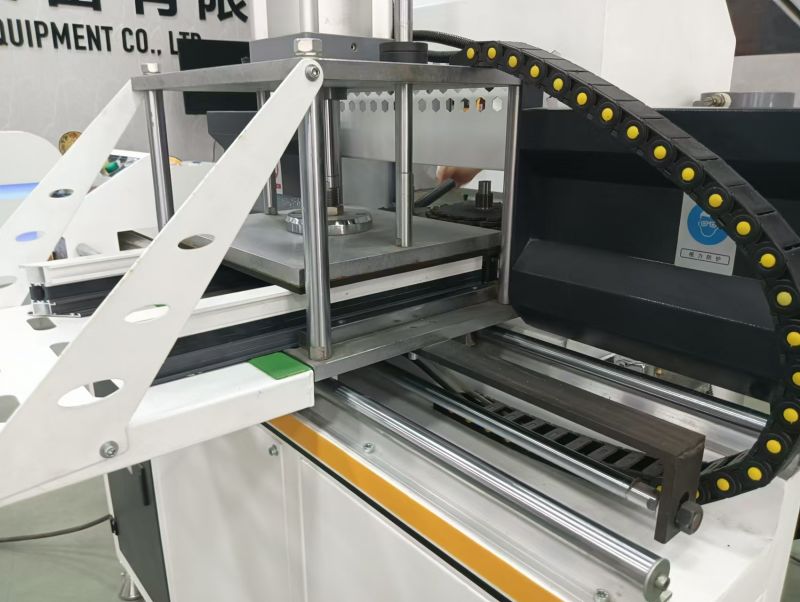

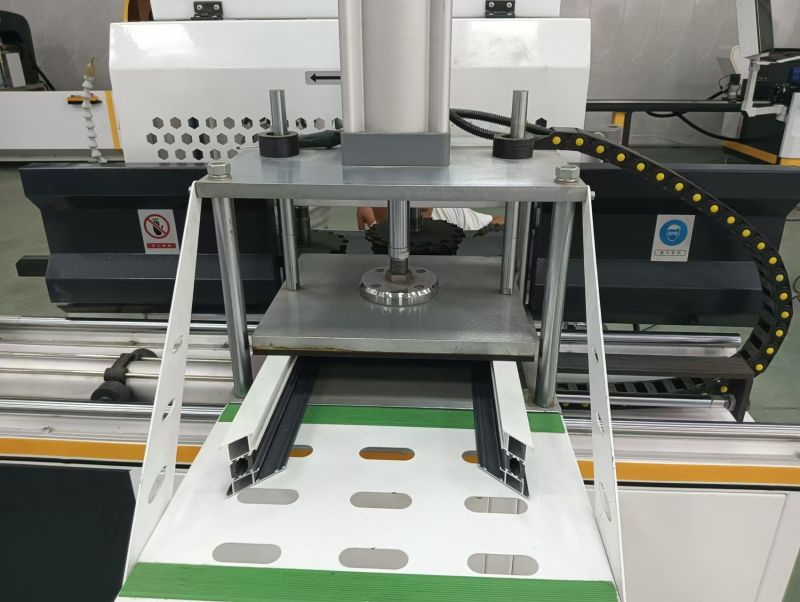

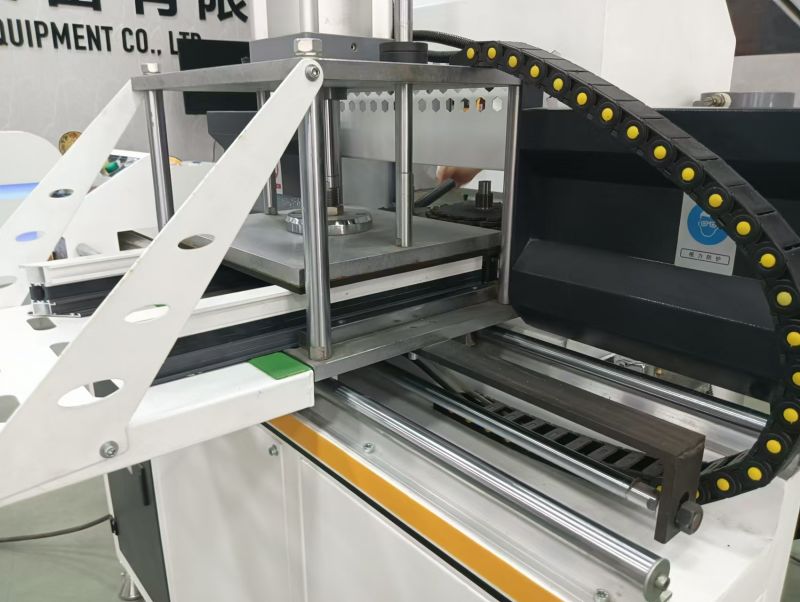

Detail photos:

Company introduction:

SETH Is a set of aluminum doors and Windows automatic production line and industrial profile processing center R & D, manufacturing,

sales as one of the high-tech enterprises.

Jinan SETH intelligent equipment co., ltd. specializes in the production of aluminum,PVC,upvc window and door machine,curtain wall and

hollow glass processing machine equipment that can meet the needs of different clients, and can also be customized according to customer

requirements of different grades of products.

The company has rich experience in production and more than 10 national patents and passed ISO9001,SGS,CE certifications,

excellent product design and development engineers, skilled production engineers, experienced production management team

and after-sales service that providing you with a strong guarantee.

The company has all kinds of equipment processing workshop, assembly workshop and quality inspection center, can independently

realize the design of equipment, processing, assembly, test one-stop flow operation, to ensure the excellent quality of equipment.

Our main products including aluminum&uPVC profile machining center, saw machine ,milling machine,welding machine,corner cleaning machine.

corner crimping machine,punching&drilling machine.

Customer is the foundation, the company in line with the " quality first, customer first" principle, Please join hands with SETH to lead intelligence.

Delivery goods:

To better ensure the safety of your goods, professional, environmentally friendly, convenient and

efficient packaging services will be provided.

Seth Company's products are strictly tested after the factory, the factory packaging for export wooden box packaging,

container shipment.

Seth controls quality at every step of the way. Avoid equipment damage during transportation,

and do anti-rust treatment before leaving the factory.

Seth worked every detail to perfection.

Choose Seth, choose rest assured, choose quality,

choose high-end aluminum-plastic doors and Windows processing equipment,

choose Seth doors and Windows processing equipment

Hot sale products:

RFQ:

Are you manufacture?

Yes, we are professional manufacture which has more than 15 years' history.

What’s the guarantee?

1). Our guarantee for 18 months.

2). 24 hour’s technical support by email or calling

3). English manual and video tutorial

5). We will provide the consumable parts at an agency price

Can we print our logo/website/company name on products?

Yes, please advise the size and Pantone Code of the logo.

What's the lead time for regular orders?

15-20 days for order quantity lower than 3 sets; For more quantity, usually 30 days.

Can I get a discount?

Yes, for the order quantity of more than 5 sets, please contact us to get the best price.

Do you inspect the finished products?

Yes, each step of production and finished products will be coming out inspection by the QC department before shipping.

If our price is higher than another company or factories?

Please check, what is the difference of the machine parts, service and guarantee, especially the machine inner electric parts,

sometimes, if machines have a breakdown, the most reason is the machine inner electric parts problem, but we use the famous and reliable parts for the machines inside.

What is the payment?

Any payment method you want, such as L/C, T/T, West-union, and so on.

Related Products

Submitted successfully

We will contact you as soon as possible