5 Axis CNC Gantry Machining Center

It is suitable for milling, drilling and other processes of all kinds of aluminum materials such as door and window lock holes, aluminum cabinet door hinges and sanitary ware profiles.

Code scanning is processing

Intelligent fixture Automatic avoidance

Spindle rotation

8 tool magzines automatic tool change

Optional vertical disk tool library

T-table is optional

Connected with ERP software, the scanning code can be automatically processed.

Profile once clamping, can complete all sawing, milling end tenon, milling keyhole slot, flow tank, pressure balance hole, installation hole and other machining sequence.

The use of moving beam moving column gantry frame structure, more stable operation, improve the machining rigidity of the machine.

5 Axis CNC Gantry Machining Center

Model:LGS-CNC-7000

Length can be customized

Feature:

1、Equipment characteristics

● Foolproof operation: on-line with ERP software, can realize automatic processing of scanning code.

● Profile once clamping, can complete all sawing, milling end tenon, milling keyhole slot, flow tank, pressure balance hole, installation hole and other machining sequence, truly realize "one person door and window production line"

● The use of moving beam moving column gantry frame structure, more stable operation, improve the machining rigidity of the machine.

● The use of high-end numerical control system Germany Siemens or Italy OSI.

● Adopt high-quality imported servo motors, ball screws, linear guides and bearings to ensure that the equipment has a high processing accuracy. High stability and reliability. The feed movement is predrawn to ensure the stability of machining accuracy.

● The machine adopts imported five-axis head, which can complete arbitrary Angle processing on all surfaces except the bottom surface.

● The use of quantitative and timed central automatic feed lubrication to ensure the stability of machine accuracy.

● Pneumatic clamping table to improve loading and unloading speed.

● The imported Renishaw interferometer is used to detect and compensate the accuracy of the machine tool.

● Adopt safety protection function to ensure safety.

Optional: Optional vertical disk tool library

T-table is optional

Machining accuracy of equipment

Positioning accuracy ±0.03mm

Repeated positioning accuracy ±0.01mm

Cutting surface roughness Ra12.5µm

2、Main technical parameters

Power supply 380V/220V 50Hz Total power 25KW

Air pressure 0.5~0.8Mpa Air consumption 80L/min

Spindle power/speed 12kw/24000r/min Spindle cone hole HSK-63F

X axis travel 7000mm Y axis travel 1000mm

Z-axis travel 550mm B-axis rotation range ±185°

C axis rotation range ±320° X axis moving speed 0~60m/min

Y-axis moving speed 0~30m/min Z-axis moving speed 0~30m/min

B axis operating speed Max7°/ 'C axis operating speed Max7°/'

Knife storage form hat type knife storage capacity 11

Lubrication/cooling system automatic lubrication/micro atomization cooling dimensions 11200×3000×3200mm

Weight 11000kg

Jinan SETH Intelligent Equpment Co.,ltd. is a professional R & D, production, sales of aluminum cnc machines, aluminum alloy doors and Windows equipment, plastic steel doors and Windows equipment, curtain wall processing equipment, industrial aluminum profile processing of high-tech enterprises.

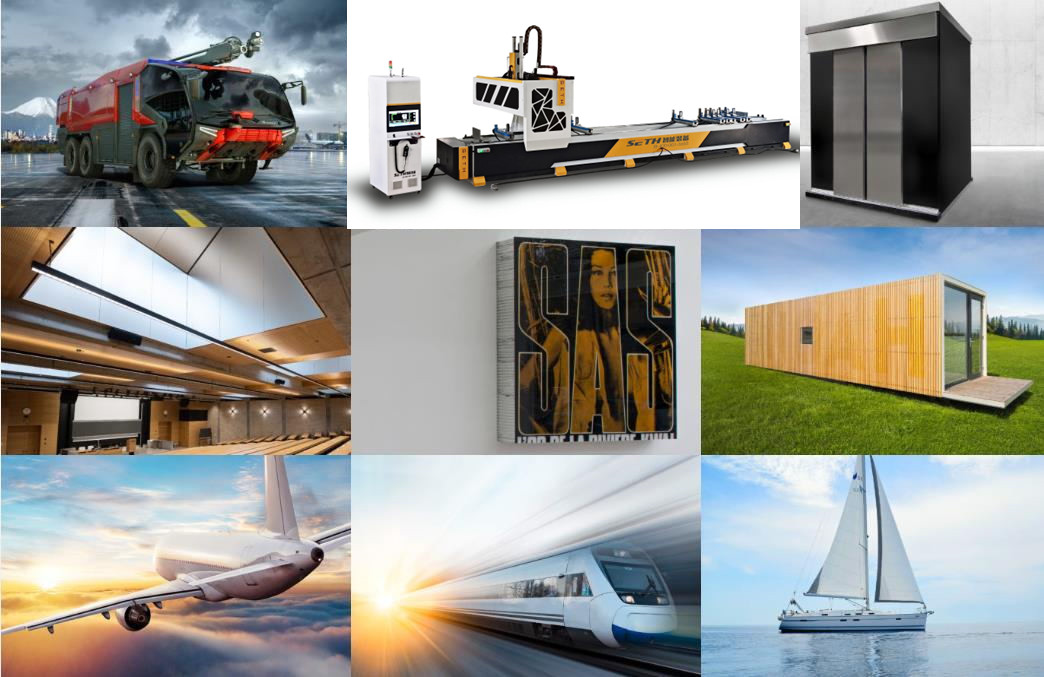

In today's society, aluminum profile equipment is widely used in various industries and plays an important role. Whether it is the construction industry, transportation industry or electronic and electrical industry, aluminum profile equipment plays an irreplaceable role.

In the construction industry, aluminum profile equipment is used to make window frames, door frames, stair railings and other components, and its lightweight characteristics and beautiful appearance make the building more modern and high-end. At the same time, the aluminum profile equipment also has the advantages of strong weather resistance and low maintenance costs, making the building more durable and beautiful.

In the transportation industry, aluminum profile equipment is widely used in the production of aircraft, trains, automobiles and other transportation components. Its high-strength, lightweight characteristics make the vehicle have better performance and energy saving effect, and enhance the competitiveness of the entire industry.

In the electronic and electrical industry, aluminum profile equipment is used to make electronic product shells, heat conductors, heat sinks and other components. The good thermal conductivity and corrosion resistance of aluminum profile equipment make electronic products more stable and reliable, and extend the service life of electronic products.

In general, the application range of aluminum profile equipment is very wide, and its excellent performance and diversified shape design make it an indispensable equipment in various industries. With the continuous progress of science and technology and the development of society, aluminum profile equipment will continue to play an important role in various fields, promoting the development and progress of the industry.

Related Products

Submitted successfully

We will contact you as soon as possible