550mm/600mm blade CNC double mitre saw for aluminum curtain wall material

Model:LJB2B-CNC-600*6000

New appearance level and unique mechanical design structure

CNC system with 550mm or 600mm diamond saw blade

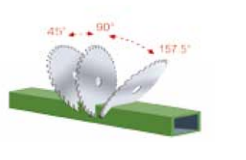

Any adjustment between 22.5° and 157.5°

optimized cutting of profiles

Equipped with vacuum cleaner to protect the working environment

the system door and window intelligent connection model, support ERP MES management software

Supports multiple data import modes

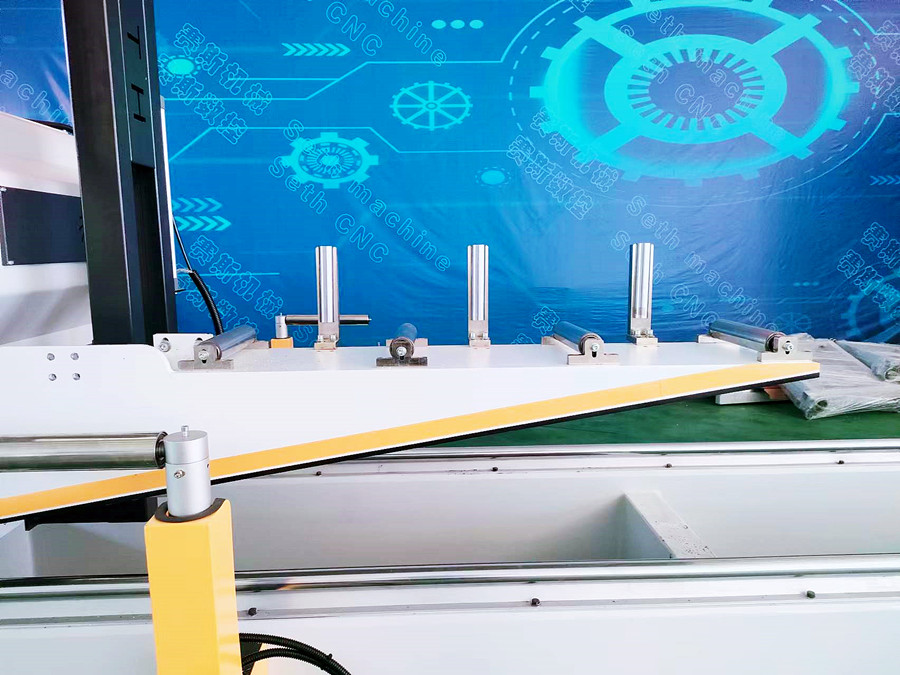

Equipped with patented rotary lifting bracket

600mm saw blade Arbitrary angle CNC double mitre saw for aluminum profile

Model: LJB2B-CNC-600*6000

Feature:

Mainly used for industrial aluminum profiles, aluminum doors and Windows, curtain wall material cutting, can also be used cutting of PVC and wood profiles.

The imported high-speed spindle direct connected motor is mounted with diamond saw blade. The saw blade feed is driven by gas-liquid damping cylinder, and the cutting is stable.

High precision imported cutting saw blade, cutting section is smooth, imported servo motor drive reducer,

The cutting Angle can be adjusted between 22.5° and 157.5°.

The import control system can realize advanced functions such as profile optimization and cutting, and can be entered to cut at one time

Cut the size of several profiles, to achieve continuous cutting of different lengths, to achieve direct processing size

In, change the cutting length without returning to the reference point.

There is a saw blade sealing device under the workbench, the chip removal effect is good, with the following opening and closing saw cover, safe

All reliable, good working environment.

Two cylinders in each machine head clamp the profile, cutting safely and reliably.

Power

380V 50HZ Saw head motor 2×3KW/ 2840r/min servo motor 1 kw Working pressure 0.5 ~ 0.8mpa Air consumption 60L/min Saw length Max6000mm MIN420mm (8200-300) Saw width Max 180mm Maximum cutting slope 45°210×220mm 90°210×300mm Sawing Angle 22.5°-157.5° Feed speed stepless speed regulation 0-3m/min Saw blade specifications ø550 × ø30 × 4.4× Z144 Dimensions 7800×1800×1500 mm Weight 2000 kg Repeat constant length accuracy ≤ 0.05mm Profile cutting Angle tolerance ±3 ' Cutting plane flatness ≤ 0.1m Roughness of cutting surface Ra12.5μm Detail photos:

This model for the system door and window intelligent connection model, support ERP MES management software door and window software docking, to achieve the integration of production and marketing control to improve production efficiency.

● New appearance level and unique mechanical design structure, making the product more stable cutting profiles easier cutting surface more smooth.

● Foolproof operation without skilled workers, to solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.

● High precision, integrated casting table, integrated spindle direct connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.

● Support a variety of data import methods: Internet, LAN, U disk, manual input, etc. It can realize the data docking of common optimization software in the market, Xinger, Changfeng, Chuangying

● Environmental protection function, unique chip removal, dust suction design, dust suction rate of 70%, clean site, reduce cleaning frequency, improve work efficiency.

● Equipped with patented rotary lifting bracket to avoid cutting errors caused by middle droop, and equipped with movable profile bracket.

Related Products

Submitted successfully

We will contact you as soon as possible