4 axis Aluminum cnc Milling Machine

Model No.:SKX4-CNC-1500

Suitable for industrial aluminum profiles, doors and Windows, curtain wall aluminum profiles.

round holes, slot holes, keyholes, profiled holes and aluminum profiles milling, chamfering, plane engraving and other processes of processing.

4 axis Aluminum cnc milling machine

Model: SKX4-CNC-1500

Feature:

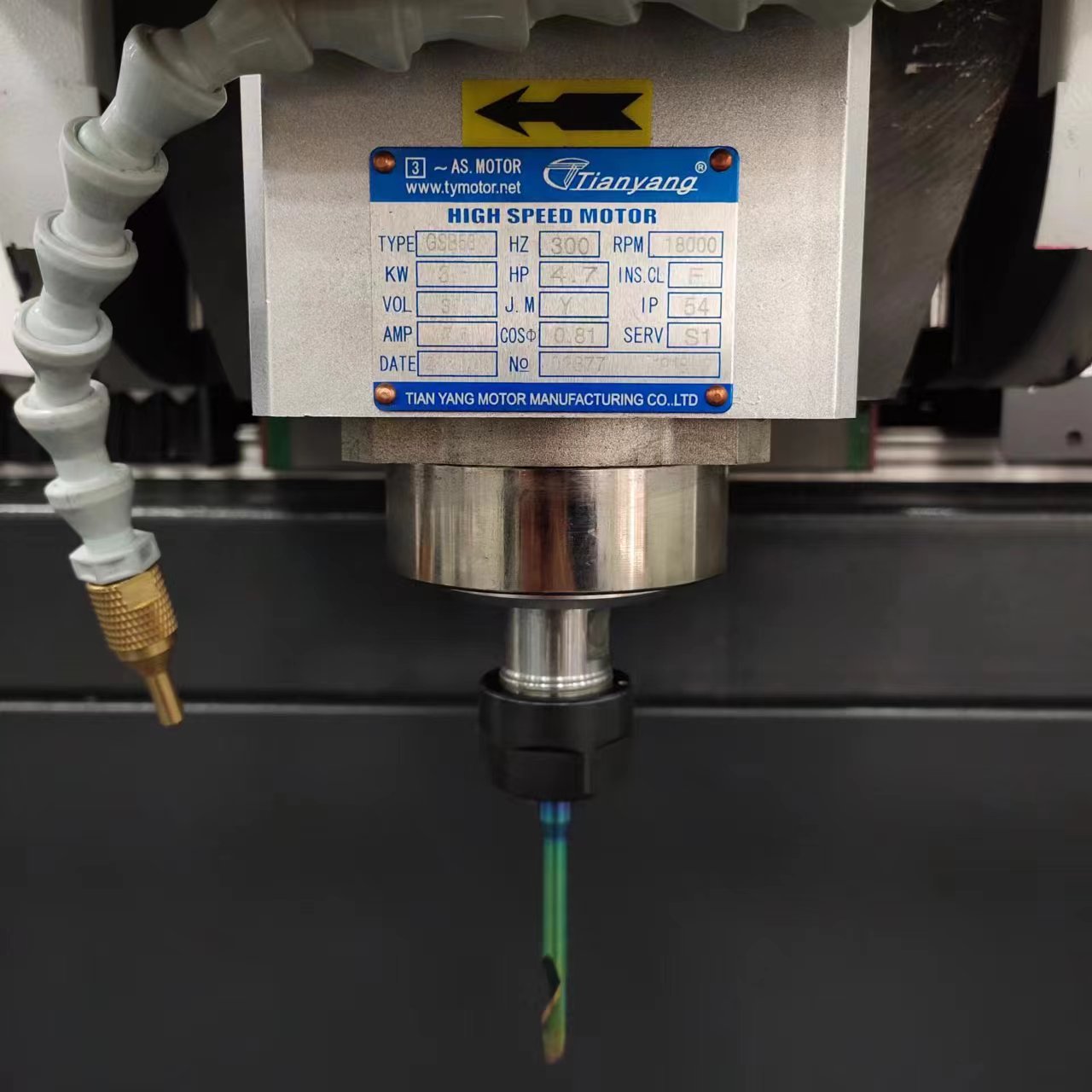

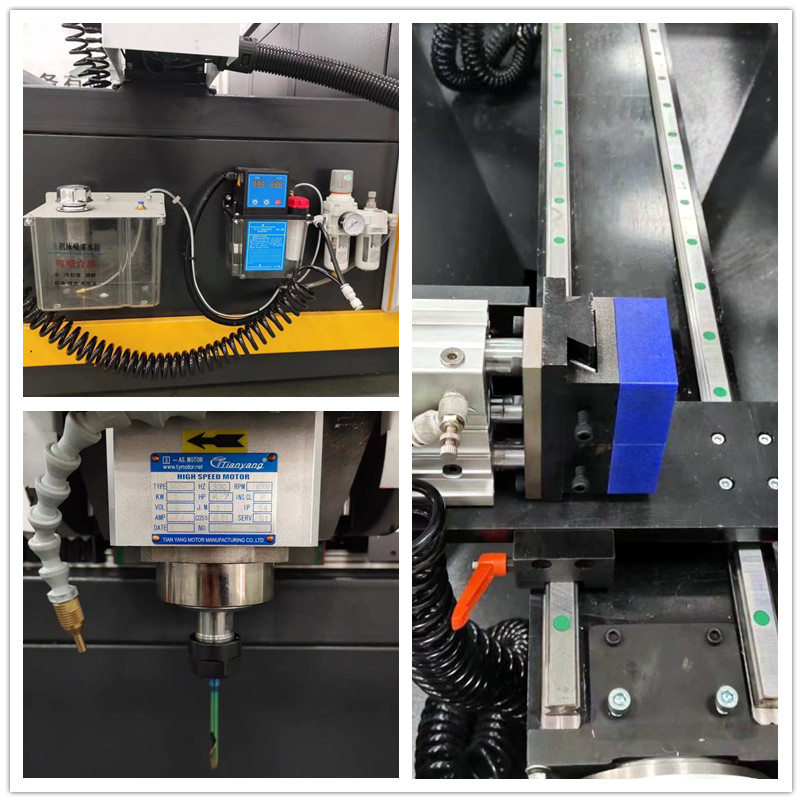

☆ The main shaft adopts air-cooled electric spindle, power 6.5kw, speed 0 ~ 18000rpm, high precision, good safety,

high reliability.

☆ Using CNC numerical control system. Equipped with professional CAD-CAM programming software. Automatic conversion

processing G code, simple operation, high efficiency, low labor intensity.

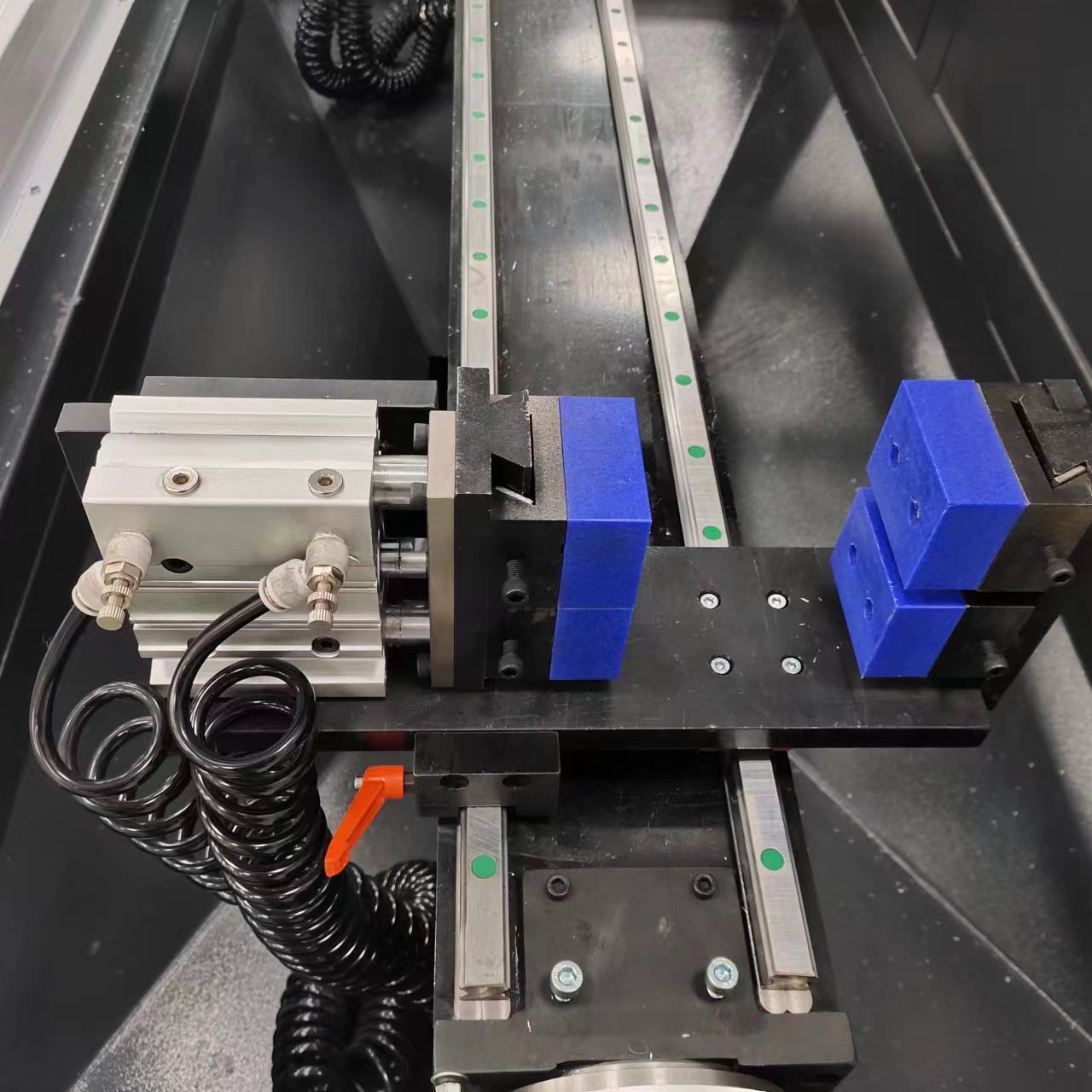

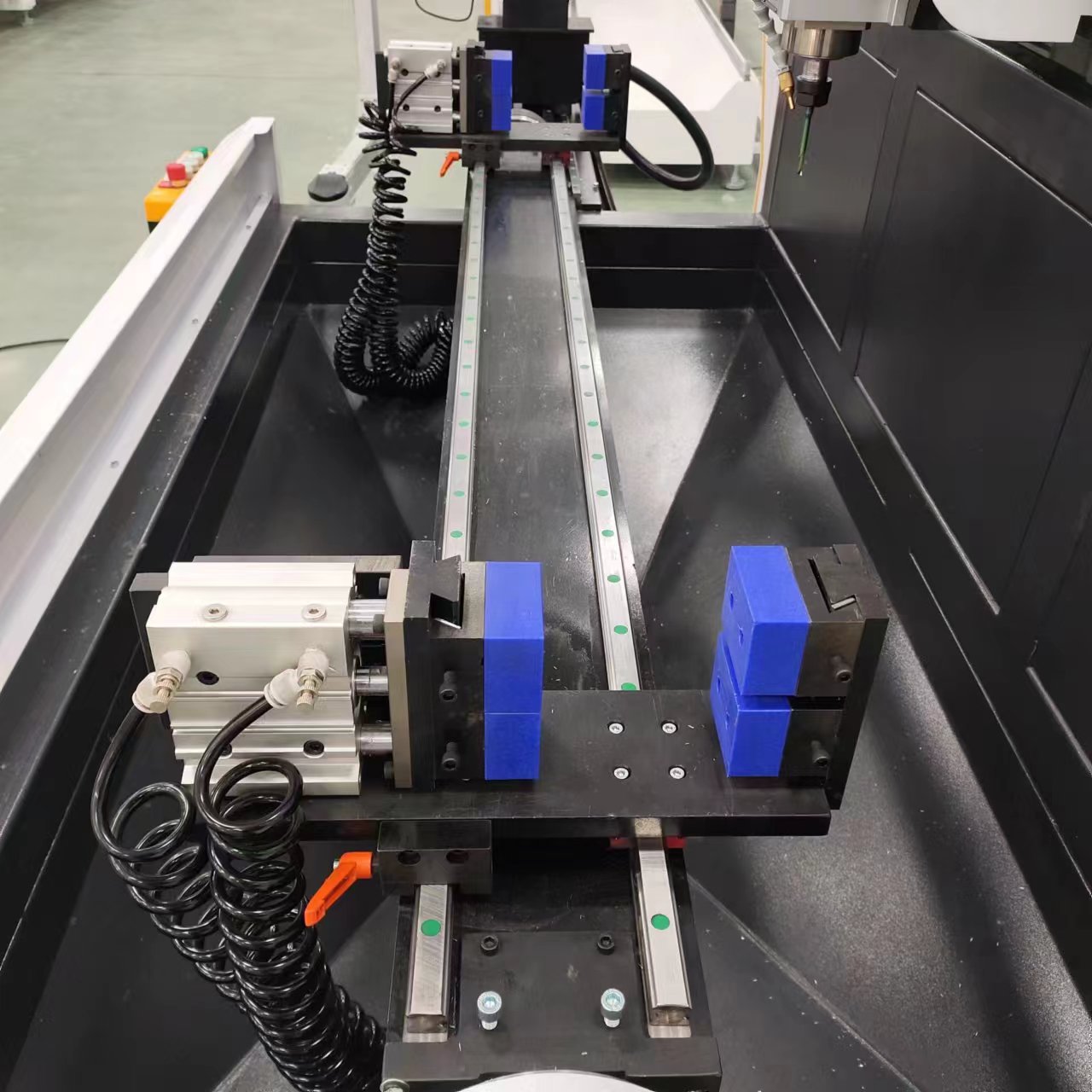

☆ All motion pairs are imported guide rails and sliders. X axis is driven by high-precision helical gear and helical rack.

Y axis and Z axis are driven

by high-precision ball screw. Smooth transmission, effectively improve the accuracy of the whole machine.

☆ Table turned 180 degrees. -90 degrees ~ 0 degrees ~ +90 degrees, the profile once clamping can achieve three side processing,

☆ processing deep through holes (shaped holes), through the table to achieve deep hole processing, improve efficiency, good quality.

☆ Adopt manual pump oil supply system, tool adopts system control spray cooling device.

☆ The main electrical parts, circuit breakers, AC contactors are made of Schneider products.

☆ The main parts of the machine tool are made of steel structure.

power supply | 380V/50Hz |

Air pressure | 0.5~0.8MPa |

Total power | 6.0kW |

Main axis power | 3.0kW |

Max rotary speed | 18000r/min |

X-axis longitudinal travel | 1500mm |

Y-axis transverse travel | 500mm |

Z-axis vertical travel | 350mm |

Y-axis speed | 50m/min |

Z-axis speed | 15m/min |

Overall dimension | 2380×2000×2200mm |

Weight | 900kgs |

We also have this model: DSK-CNC-3000DK CNC machining center. and the length can be customized:

1000mm,1200mm,2000mm,2500mm,3000mm,3500mm exc.even we have 9m 4axis cnc maching center,

5 axis gantry cnc machining center. Suitable for new energy auto parts, aluminum motor shell, rail transit, doors and Windows curtain wall,

photovoltaic solar energy, space capsule aluminum parts, car chassis, anti-collision beam processing

Package:

After careful preparation and efficient coordination, SETH successfully completed the delivery of the latest batch of goods,

providing customers with quality services and products.

The shipment covers multiple shipments from different regions, including high-end door window manufacturing machines,cutting saw,

end milling, drilling and milling machine, corner combining machine, copy router, mitre saw of all aluminum processing machinery.

SETH The team is meticulous in the preparation, packing and transportation process to ensure that the goods are safely delivered to the destination in the shortest possible time.

The customer expressed a high degree of satisfaction with the delivery of this shipment and expressed their trust and recognition of SETH.

At the same time, SETH will continue to work hard, adhering to the professional service attitude and efficient work efficiency,

to provide customers with more quality products and services.

In the future, SETH will continue to be committed to improving the efficiency and quality of goods delivery,

constantly improving the supply chain management system, and creating greater value and returns for customers.

We look forward to working with more customers to share the joy of success and growth. Thank you for your support and trust in SETH!

Seth company is is a national high-tech enterprise dedicated to providing products and solutions for

intelligent manufacturing of doors and Windows. The product direction is mainly for intelligent equipment

for multi-product custom doors and Windows, including a new generation of intelligent workstation ,drilling and milling,

aluminum cutting center, Aluminium Window Fabrication Machinery,cnc machining center, intelligent double head mitre saw,

CNC end milling and Aluminum Window Corner Crimping Machine,punching machine,bending machine other products.

In the future, we will pay full attention to the investment in equipment research and development and innovation,

and make more refined and perfect products. At the same time, let some key processes to achieve artificial replacement,

the use of the Internet of things, cloud computing and other new generation of information technology combined with modern manufacturing technology,

to promote the production of doors and Windows to intelligent development, to create incremental value for users and the industry.

Related Products

Submitted successfully

We will contact you as soon as possible