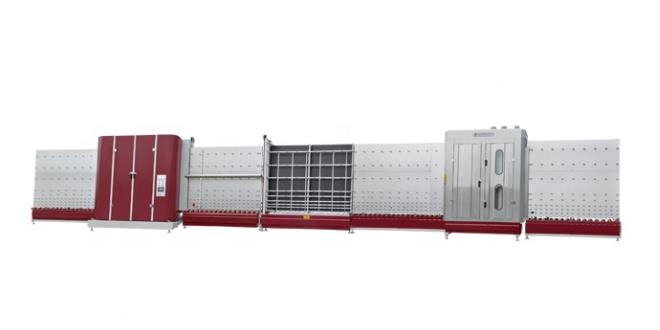

Auto Insulating Glass Machine

Italy Technical level of Production ,Installation and Mechanical.

More practical and convenient design of pressing part about vacuum , pneumatic driving.

Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times.

Reasonable hollow glass pressing process to keep all roller got much more longer life also avoid to break any glass.

It could increase working speed as 45m/min of glass to keep high efficiency (normally 900 pieces in 8 hours by different size insulating glass production).

Italy Technical level of Production ,Installation and Mechanical.

Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass --- two or three pieces of glass or different sizes of glass .it adjust the size of different glass by servo motor to realize high auto and more exact running.

More practical and convenient design of pressing part about vacuum , pneumatic driving. It can deal with two or three pieces of glass and curtain walls .

Reasonable hollow glass pressing process to keep all roller got much more longer life also avoid to break any glass.

It could increase working speed as 45m/min of glass to keep high efficiency (normally 900 pieces in 8 hours by different size insulating glass production).

The frame is welding by 2.75 mm International Rectangular pipe with high strength structure.

It is a completely automatic insulating glass production line (can produce LOW-E insulating glass).

2-monitor using system-Temperature/Speed/Production volume-Mechanical trouble check-Whole line control function with 1 monitor.

It realize glass pressing automatic outside press machine. Press glass-normal insulted glass,triple and step insulated glass (selective)and curtain wall glass and abnormity insulated glass.

Full distance automatic changeable frequency speed adjustment, which can save work waiting time and improve production efficiency.

Press board can open, easy to examine an repair

Sections of Washing parts

Imported anti-static long life brushes, 6 motor for 6 brushes,11kw high efficient drying fan, powerful filtration system with separate filter;High temperature resistant brush with spray washing system to keep all clean process more easier , faster ,thorough and comprehensive.

Welding by stainless steel with high strength structure ,double deck of the bottom floor; Top ceiling of it made by 12mm Thickened stainless steel plate, the bottom is made by 5mm thick stainless steel ,the lateral is made by 2mm thick stainless steel.

All Spare parts in washing box is made by Stainless or Waterproof material to keep all section long and stable working life.

Air knife can be adjusted according to the width of the thickness of the glass.

European style fans with air inlet heating in winter to make sure drying effect.

Cleaning tank, air-dried container, air knives made of stainless steel, elegant appearance

Six Germany brushes .

Air-dried container and fans circulating air system, the blade structure air blower keep temperature about 40℃ without the heating up.

Related Products

Submitted successfully

We will contact you as soon as possible