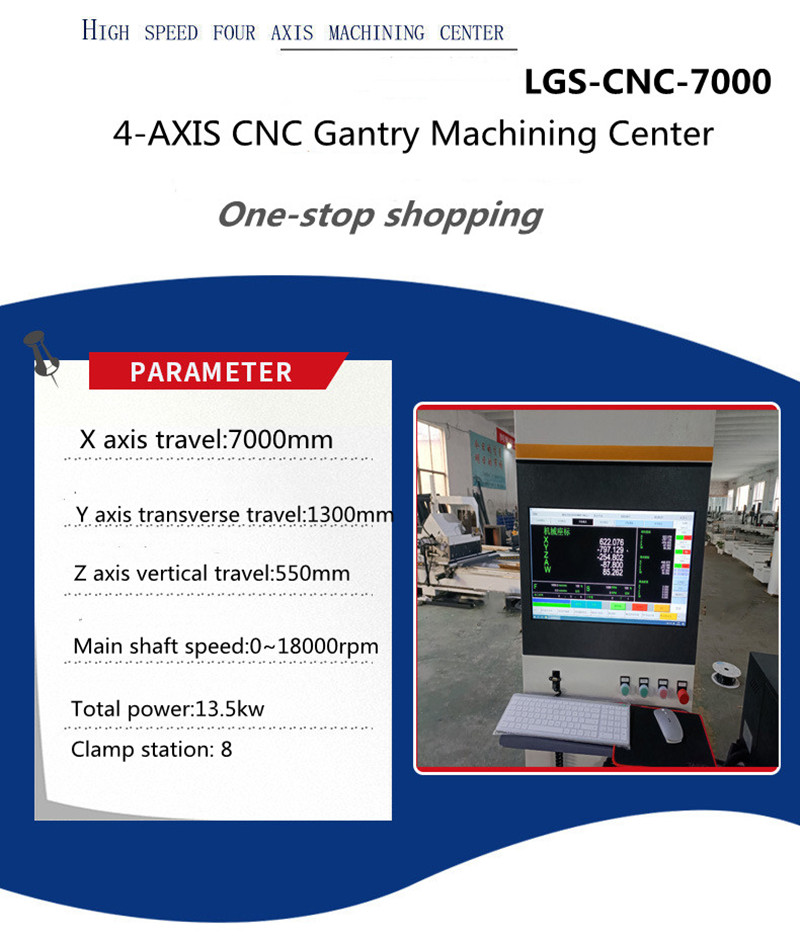

New High Speed Four Axis CNC Machining Center

Aluminum CNC machining center ,It is suitable for all kinds of holes and slots milling processing of aluminum curtain wall or industrial aluminum profiles. aluminum window door making.With 3D programming software, it can perfectly realize drilling and milling processing.

Using advanced industrial CNC system,friendly machine interface and operation is simple.

ATC(automatic tool change) with 6 tool,12tool,24 tools exc.

One clamping profiles complete milling,drillig, tapping,chamfering,grooving and other multi-functional precision machining.

Adopt imported high precision linear guideways,ball screws,gear racks and servo motor.

The number of the tool magazine can be made as clients' requrement.

Multipe safety protection structure to ensure worker safe.

1.Gantry cnc machining center adopt the original imported control system, servo motor, with high-quality ball screw, linear guide and bearing and other mechanisms to ensure that the equipment has a high machining accuracy. The position of the fixture can be automatically placed.

2. Double table can simultaneously carry out two pieces or two kinds of profile processing, interactive feeding, non-interference.

With 12 station tool library, automatic tool change.

3. The machine tool has high precision, the spindle is supported by high precision double ball bearing, low noise, high precision and good stability.

4, the electric four-station tool rest adopts precision tooth disk positioning, high positioning accuracy.

5, tail frame with fast CAM clamping device, high efficiency. There is a device in the tailstock sleeve to prevent the bit from rotating, which avoids damage to the inner hole taper of the tailstock sleeve caused by the bit rotating due to misoperation, and effectively protects the tailstock components.

6, the numerical control system can choose the hybrid stepper motor drive or AC servo motor drive, can also be selected according to user requirements other systems, easy to operate, especially suitable for complex profiles or high precision mass profile processing.

Power supply |

Power supply | 380V 50Hz |

Total power | 9 Kw |

Working pressure | 0.6~0.8 MPa |

Maximum speed | 18000rpm |

X axis longitudinal travel | 7000mm |

Y axis transerve travel | 1300mm |

Z axis vertical travel | 550 mm |

X axis velocity | 0-60m/min |

Y axis, Z axis velocity | 0-30m/min |

Dimensions | 11300x2350x2550mm |

Weight | About 4500 kg |

Related Products

Submitted successfully

We will contact you as soon as possible