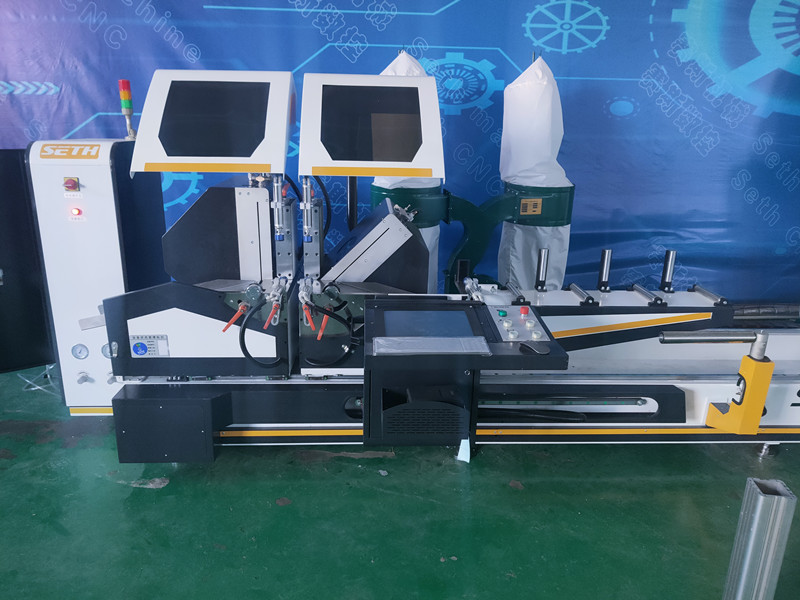

Heavy Duty CNC Double Head Precision Cutting Saw

Heavy Duty CNC Double Head Precision Cutting Saw is mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.

The double-head cutting saw for aluminum profiles is a highly efficient piece of equipment for cutting aluminum profiles. It has multiple advantages, including:

High precision: The saw uses advanced technology to ensure precise cutting of aluminum profiles, resulting in high-quality finished products.

Versatility: The double-head design allows for cutting of different angles and lengths of aluminum profiles, making it a versatile tool for window and door manufacturers.

Efficiency: The saw can cut two profiles simultaneously, which greatly increases production efficiency and reduces labor costs.

Safety: The saw is equipped with safety features that prevent accidents and injuries during operation.

Durability: The saw is made of high-quality materials that are designed to withstand heavy use, ensuring long-lasting performance and durability.

Overall, the double-head cutting saw for aluminum profiles is an essential tool for manufacturers who prioritize efficiency, precision, and safety in their production processes.

● Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.

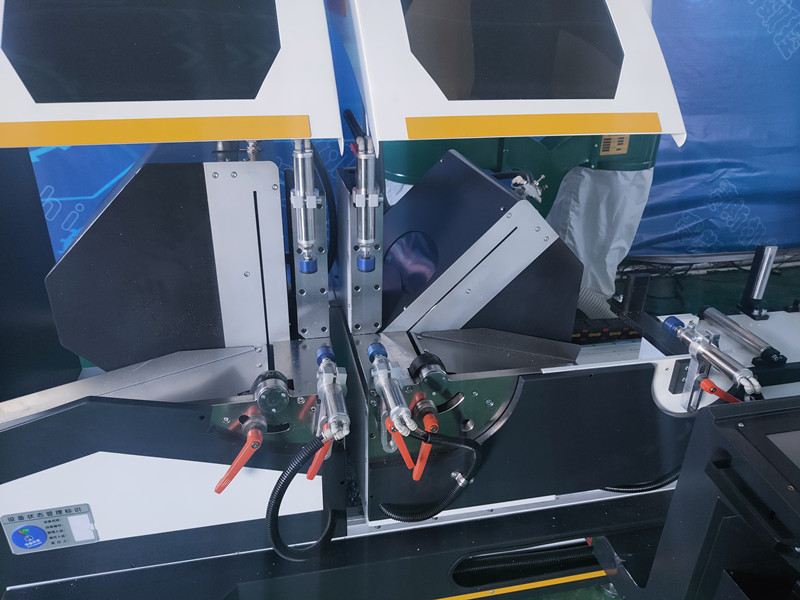

● High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.

● Supports multiple data import modes:Internet, LAN, U disk, Bluetooth, manual input, etc. Can realize the market common optimization software data docking, New gel, changfeng, chuangying

● Environmental protection function, unique chip removal, vacuuming design, vacuuming rate of 70%, clean site, reduce cleaning frequency, improve work efficiency.

●It is equipped with patented rotary lifting bracket to avoid cutting error caused by middle droop, and equipped with movable profile bracket.

● The latest arc cutting technology, sawing section is safer, faster and more reliable.

Main specification and technical parameter

Power supply | 380v 50hz |

Saw head motor | 2 × 3KW/3000r/min |

Working pressure | 0.6~ 0.8MPa |

Air consumption | 60L/min |

Cutting length | Max5000mm min 280mm Short cutting function is the shortest 200mm |

Cutting width | Max 150mm |

Max. Cutting slope | 45°150× 170mm 90°150×345mm |

Max. square tube cutting | 150×200mm |

Cutting angle | 45degree 90degree |

Feeding speed | continuously viable 0-4m/min |

Saw blade specification | ø500 × ø30 × 4.4 × Z120 |

dimension | 6550× 1300× 1800 mm |

weight | 2000kgs |

Accuracy of repeated fixed length | ≤ 0.1mm |

Allowance of section cutting angle | ± 3’ |

Flatness of cutting profile | ≤ 0.02m |

Roughness of cutting profile | Ra 12.5 μm |

Item | name | Brand | Origin |

1 | CNC system | Delta | Taiwan |

2 | Computor PC | Delta | Taiwan |

3 | touch screen | Delta | Taiwan |

4 | driver | Delta | Taiwan |

5 | servo motor | Delta | Taiwan |

6 | automatic breaker | Schneider | France |

7 | phase sequence protection relay | Schneider | France |

8 | a.c. contactor | Schneider | France |

9 | thermal protector | Schneider | France |

10 | switching power supply | Schneider | France |

11 | relay | Schneider | France |

12 | Low voltage switch button | Schneider | France |

13 | terminal | Honeywell | USA |

14 |

| GMT | Shenzhen china |

Related Products

Submitted successfully

We will contact you as soon as possible