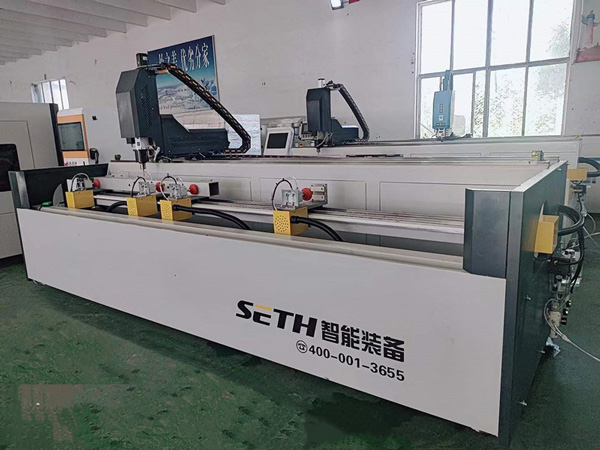

Aluminum Profile CNC Machining Center

Used for milling aluminum doors, Windows, curtain walls and industrial aluminum. CNC control processing process,automatic completion of station conversion.

The design goal of the machine is high speed and high precision machining, and the structure design and power ratio of the machine are carried out. Enhanced, so that the equipment has a high strength bed and moving parts, the use of efficiency has been greatly improved.

Wide range of processing width and processing height to meet the processing of variety of profiles.Adopt high speed and high precision motorized spindle. X axis adopts high precision helical gear and helical rack, Y axis and Z axis adopts high precision ball screw drive.Automatic tool change type, the equipment according to the need for automatic tool change processing, 6 tool library design.

Power supply | 380V/50Hz |

Working pressure | 0.5~0.8MPa |

The total power is | 13.5kW |

Electric spindle power | 9.6kW |

Maximum spindle speed | 24000r/min |

X axis travel | 4000mm |

Y-axis stroke | 640mm |

Z-axis travel | 440mm |

X axis speed | 50m/min |

Y-axis velocity | 15m/min |

Z-axis speed | 15m/min |

Overall size | 5630×2780×2500mm |

It weighs about | 2100kg |

CNC system | Hanslaser |

electric parts | Schneider |

air cylinder | AirTAC |

solenid valve | AirTAC |

Related Products

Submitted successfully

We will contact you as soon as possible