4 Axis CNC Gantry Machining Center

Fool operation: on-line with ERP software to realize automatic processing of scanning code.

Suitable for milling, cutting, and carving various holes and grooves in curtain walls and industrial aluminum profiles.

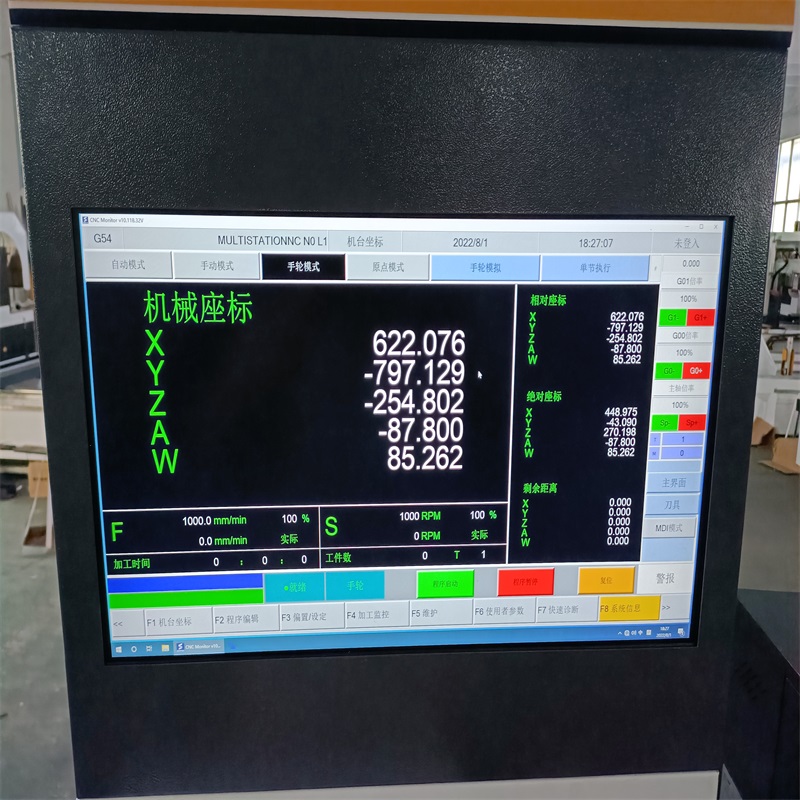

4 axis servo motor ,cnc system with 3D programming software.

High processing accuracy.

Large processing range

Equipped with 12 station tool library.

The position of fixture can be placed automatically.

Automatic tool changing, and self cutting processing.

Customizable 9-meter extension model.

Positioning accuracy ±0.03mm

Repeated positioning accuracy ±0.02mm

Cutting surface roughness Ra12.5µm

4 Axis CNC Gantry Machining Center

Model:LGS-CNC-7000

Feature:

This kind of high speed 4 axis cnc machining center is suitable for milling all kinds of holes and slots of aluminum curtain wall or industrial aluminum profiles.

Suitable for profile mounting holes, flow flume, lock holes, shaped holes, end milling and other processing processes gantry frame structure: more stable operation.

With 3D programming software, it can perfectly realize drilling and milling.

Adopt original imported control system, servo motor, with high quality ball screw, linear guide pair and bearing and other mechanisms

to ensure that the equipment has a high machining accuracy.

The position of fixture can be placed automatically.

Double table can simultaneously carry out two or two kinds of profile processing, interactive feeding, non-interference.

With 12 station tool library, automatic tool change.

The high-speed motorized spindle imported from Italy can complete the processing of any Angle within ±90°, with

High work efficiency.

Data Sheet:

X Longitudinal stroke of shaft | 7000mm |

Y Longitudinal stroke of shaft | 1300mm |

Z Longitudinal stroke of shaft | 550mm |

X axis speed | 0-60m/min |

Y axis speed | 0-30m/min |

Z axis speed | 0-20m/min |

speed of mainshaft | 0-24000rpm |

Spindle power | 12KW |

Range of spindle rotation | -90°~0°~+90° |

tool magazine | 12 tool |

Maximum installation length of tool | 165mm |

Installed power | 23KW |

Fixture station | 8 |

Range of machining dimensions | 650*250*7000mm 435*250*7000mm |

dimension | 11300*2350*2550mm |

weight | 5000Kg |

Stability and accuracy: Flat guide rails are used on all axes, and high-quality imported servo motors, ball screws, linear guides and bearings are used to ensure high stability and reliability of the equipment. The machine tool adopts five-point support for higher stability.

Strong motorized spindle: In order to obtain the best processing performance, the machine adopts the original Italian HSD motorized spindle speed up to 24000 revolutions per minute, can complete the processing of any Angle within 180°, with extremely high work efficiency, to achieve high-speed milling, high-speed drilling and high-speed tapping performance.

Tool library: The perfect 9-tool library design guarantees fast tool change and accuracy.

Perfect control technology: The use of German PA control system, perfect operation interface, only one clamping can be completed

Surface processing. Exclusive AI profile control, this advanced feature guarantees high accuracy at high cutting speeds. Simultaneously avoid

Tool path errors occur at high speed machining to ensure smooth acceleration.

Smart fixture: Powerful software support, fixture can be placed automatically. The fixture can be freely combined to process the workpiece more convenient.

Ultra-large processing range: the unique ultra-large processing range in China.

Double work area: Double work area processing interactive feeding without stopping, higher efficiency.

Lubrication: The use of advanced micro lubrication system, improve the working environment more energy saving and environmental protection.

Protection: humanized infrared safety protection function to protect the safety of operators.

Can be customized 9 meters long model.

Positioning accuracy ±0.03mm

Repeated positioning accuracy ±0.02mm

Cutting surface roughness Ra12.5µm

Related Products

Submitted successfully

We will contact you as soon as possible