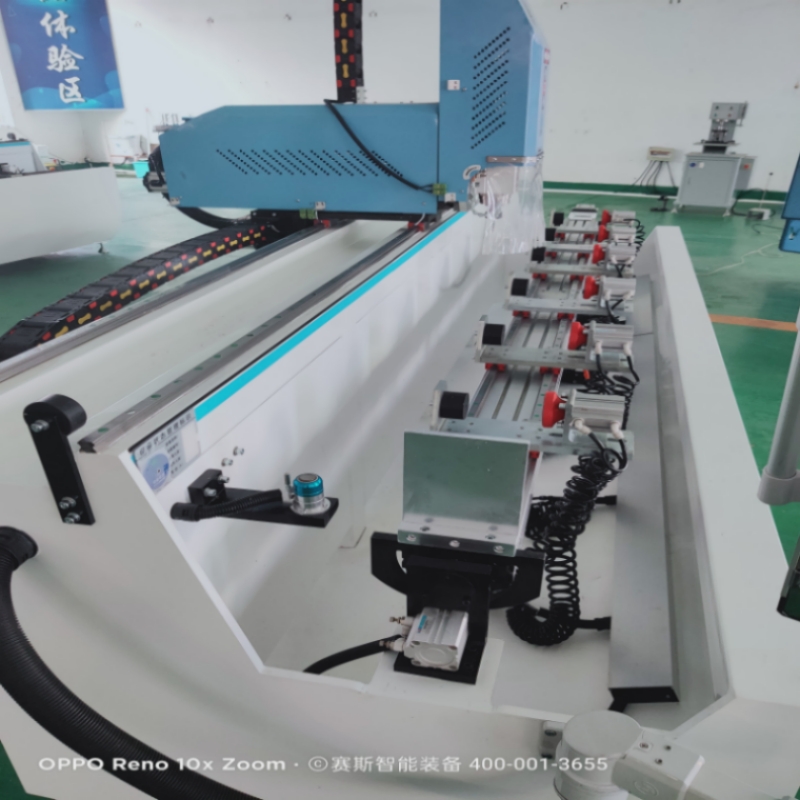

Aluminum profile 3+1 axis CNC drilling and milling machine

1. The machine is used for drilling holes, milling grooves, processing round holes and special-shaped holes,plane engraving of aluminum alloy profiles.

2. Adopting CNC numerical control system,Equipped with professional CAD cam programming software。 By using programming software to transform and process G code automatically, easy operation, high efficiency and low labour intensity.

3. Adopted the electric spindle, high precision, high safety and reliability.

4. X axle adopts high precision helical gear and rack, Y and Z axiss adopt high-precision ball screw trassmission, steady transmission and high precision.

5. workbench can turn 180°,-90°0°+90°, it can realize material three-sides section processing by clamping one time, it can process deep and special-shaped holes through workbench turning, high efficiency and precision

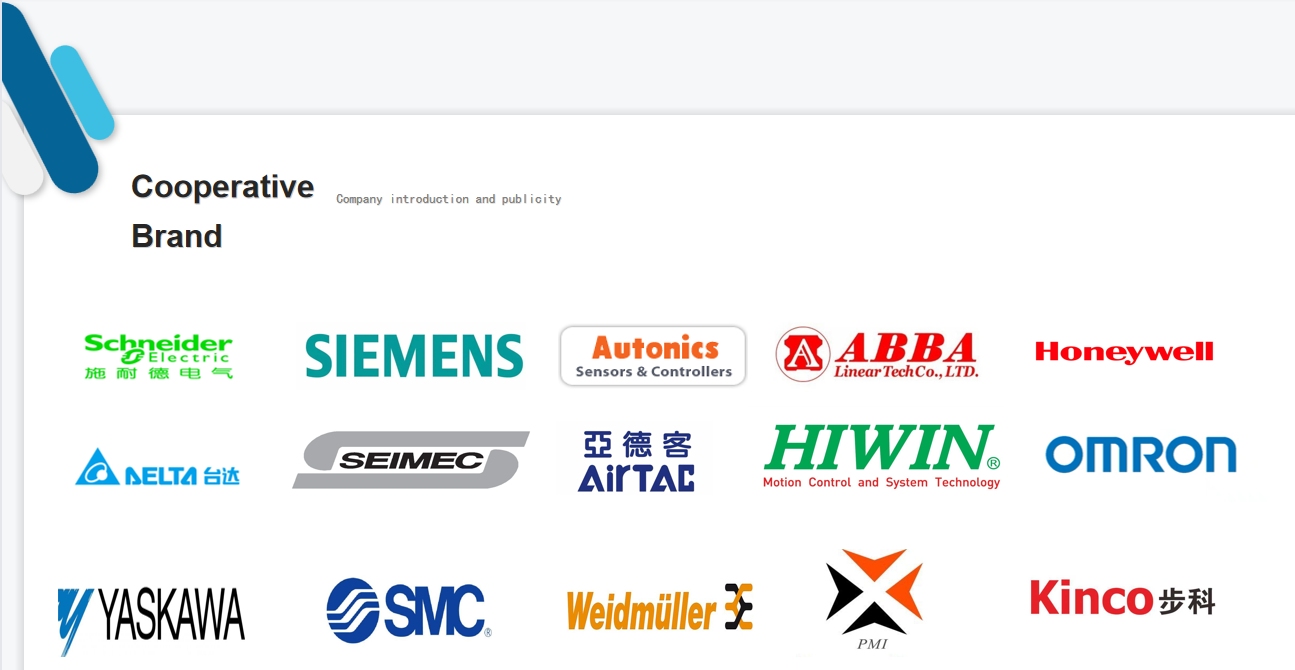

6.The main electrical components are made of Schneider products from France。

| Model | SKX3+1-CNC-3000 |

| Air Pressure | 0.6~0.8MPa |

| Power supply | 380v/50hz |

| Total Power | 6.5Kw |

| Spindle | 3.5KW |

| Max rotary speed | 18000r/mim |

| X-axis speed | 50m/min |

| Y-axis speed | 15m/min |

| Z-axis speed | 15m/min |

| X -axis longitudinal travel | 3000mm |

| Y -axia transverse travel | 500mm |

| Overall dimension | 4180x1600x2200 |

Related Products

Submitted successfully

We will contact you as soon as possible