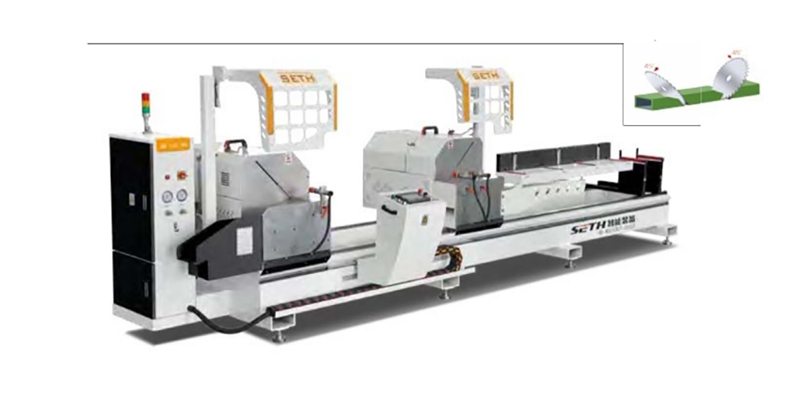

Double Head 45° Specially Cut Precision Saw Machine

It is mainly used for cutting and blanking system door and window profiles at 45° angle, and can also be used for cutting and blanking plastic profiles.

Adopt square guide rail, with high precision of repeated positioning.

The machine adopts numerical control technology, and can complete automatic positioning, cutting and blanking of profiles with different specifications and sizes.

LJZ2Z-CNC-550*4300

Using cemented carbide saw blade, the outer diameter can reach 550,

the linear speed is high, and the machining precision is high.

High transmission precision, accurate positioning and stable operation.

High precision spindle motor makes the saw blade rotate stably.

Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.

Adopt micro spray cooling device.

When the machine works, the saw blades with two saw heads can cut at the same time or separately.

The machine head is fixed at an angle of 45° to ensure stable precision in long-term use.

With the saw blade from back to front, the sawing profile is safer and more reliable, and the sawing height and width are very large.

Power supply | 380V/50Hz |

Saw head motor | 2×3.0kW 2840r/min |

Working pressure | 0.6~0.8MPa |

Air supply | 60L/min |

Cutting length | 320~4250mm |

Cutting width | Max. 170mm |

Cutting height | Max. 280mm |

Max. cutting slope | 45°135×180mm |

90°135×220mm | |

Cutting angle | 90°、 45° |

Feeding speed | Infinite speed variation0~3m/min |

Saw blade specification | Ф550×4.4×Ф30 Z=144 |

Overall dimension | 5800×1800×1500mm |

Weight | About 2000kg |

Related Products

Submitted successfully

We will contact you as soon as possible