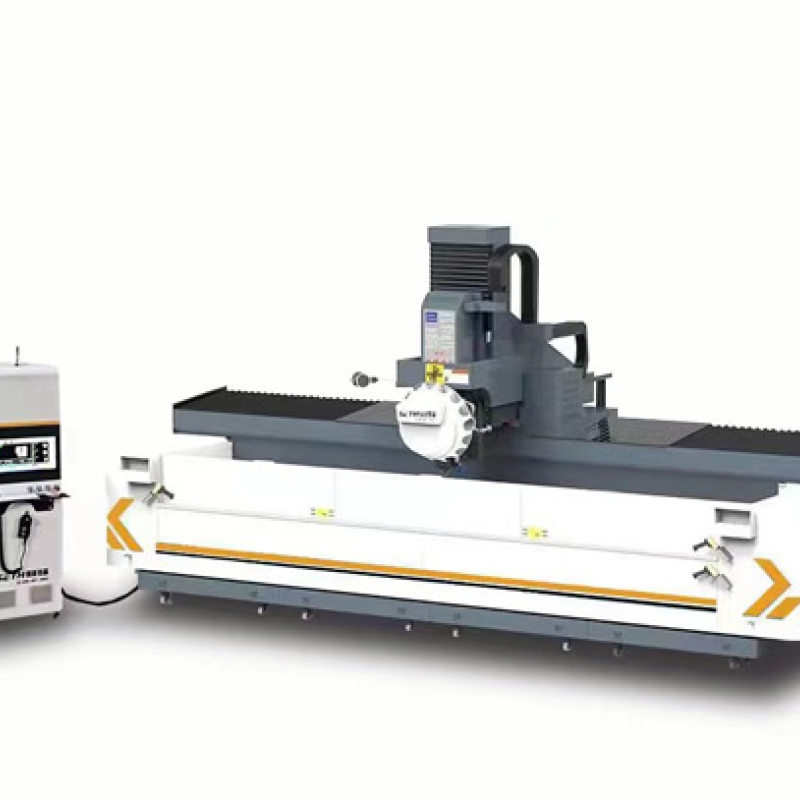

1. Use international special CNC system;2. Suitable for processing various lengths of steel, aluminum, copper metal and non-metal;3. Adopt double cantilever design structure, increase the stability and rigidity of equipment, suitable for heavy cutting, improve the machining accuracy;4. Adopt large inclined sheet metal organ cover protection;5. BT40/BT50 spindle taper hole, increase the machine rigidity, processing efficiency, precision, high strength;6.

Contact Now

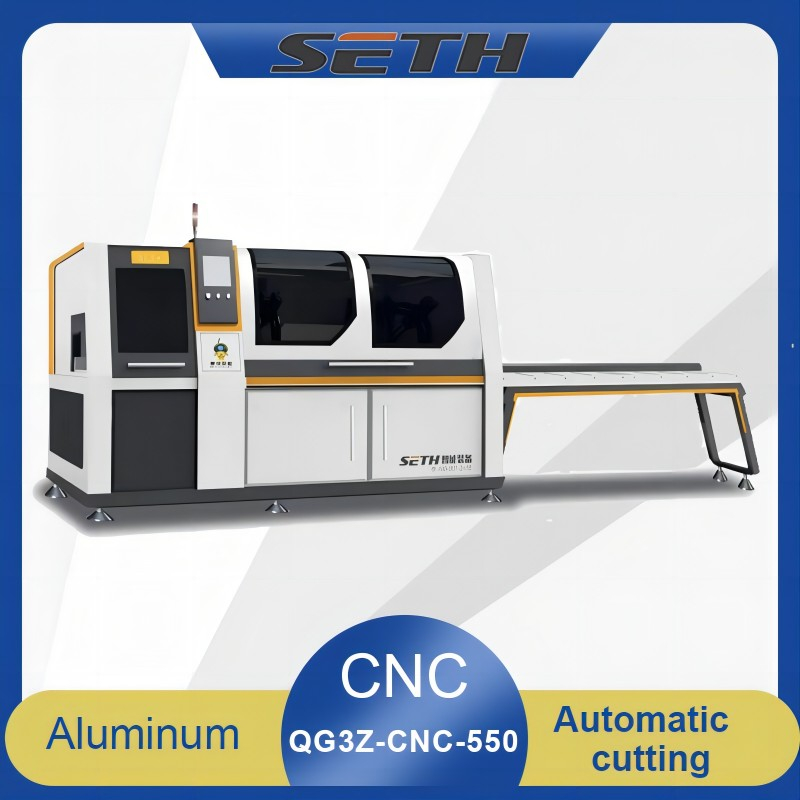

☆ Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.☆ Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.☆ High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated air-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.☆ Supports multiple data import modes:Internet, LAN, U di

Contact Now

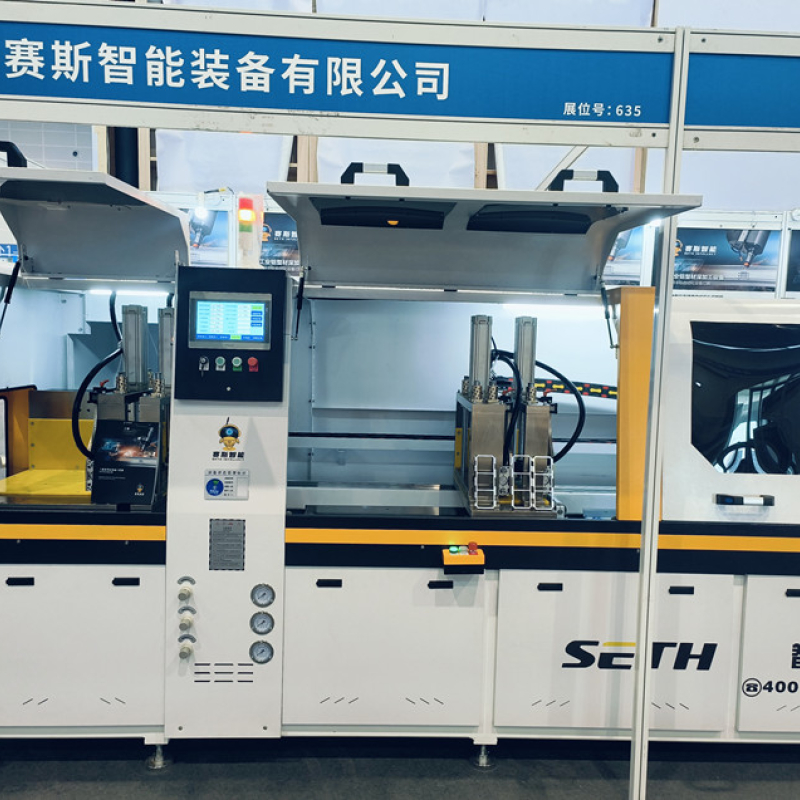

LMB-120It is suitable for angle-code punching and riveting connection of aluminum doors and windows.

Contact Now

LMB-SZ-120ZIt is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

LMB-SZ-120ZIt is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

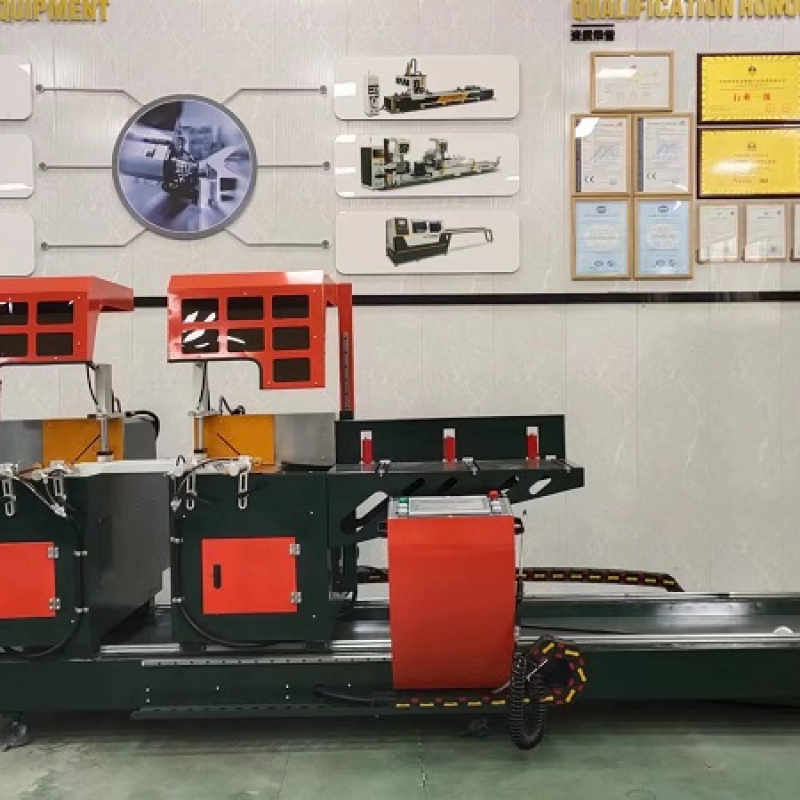

Power source: 380V 50HZ Total power: 15KWSaw head motor: 13KW/ 2840r/min Servo motor: 2×1KWWorking pressure: 0.6 ~ 0.8MPa sawing length: 0-6000mmCutting width: max 450mm Cutting height: max 230mmCutting Angle: 90° Feed speed: stepless speed regulation 0-3m/minSaw blade specification: ø650 × ø30 × 5.0× Z120 Repetitive cutting length accuracy: ≤ 0.05mmProfile cutting Angle tolerance: ± 3 'cutting surface roughness: Ra12.5μmDimensions: 11000× 2100× 1700 mm Weight: 3300kg

Contact Now

1. Used for welding colorful profiles, and can clean welding slag in one time, without showing the bottom color.2. Co-extrusion tool adopts aluminum alloy material, precisely proceed with high-frequency quenching.3. Equipped with automatic blowing system, can improve work efficiency.4. PLC control, pneumatic drive, simple operation, stable capability.5. Weld three-point, two point, single point, transom, cross -transom and special angle.

Contact Now

Aluminum CNC Double Head Mitre Saw MachineModel: LJZ2-CNC-550*6000First, Mainly used for aluminum curtain wall material. The cutting of the window material can also be used for the cutting of plastic profiles, the use of diamond saw blade.the outer diameter can reach 500-600mm, and the speed is high.

Contact Now

Power supply380V 50HzTotal power9.9 KwMain shaft powerS1:3.5kwWorking pressure0.6~0.8 MPaMaximum speed18000rpmX axis travel3500mmY axis travel380mmZ axis travel350 mmX axis velocity50000 mm/minY axis, Z axis velocity15,000 mm/minDimensions4180x1600x2200mm WeightAbout 1600 kgx axis travel60m/minY aixs travel45m/minZ aixs travel30m/min

Contact Now

CNC system is adopted. Equipped with professional CAD-CAM programming software. Automatic conversion processing G code, simple operation, high efficiency, low labor intensity.All motion pairs are imported guide rails and sliding blocks. X axis is driven by high-precision helical gear and helical rack. Y axis and Z axis are driven by high-precision ball screw. Smooth transmission, effectively improve the accuracy of the whole machine.Table flipped 180 degrees.

Contact Now

1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

CNC Double Head Cutting Mitre Saw LJZ2-CNC-550*4300Our CNC double head cutting mitre saw numerical control technology and can complete automaticpositioning cutting of different sizes of profiles.Selected high-quality aluminum carbide saw blade, outer diameter up to 500,high wire speed,high processing accuracy.CNC transmission adopts high standard rack and pinion, high transmission accuracy,accurate positioning,stable work.High precision spindle ensures stable rotation of saw blade and effectively improves surface qualityof workpiece.Gas-liquid damping cylinder to achieve uniform feed

Contact Now

LXFG2-270*115It is suitable for copying all kinds of holes, tenons and grooves, running water troughs, etc.

Contact Now

☆ The feed system adopts imported linear guide pair, high precision and good stability☆ Driven by servo motor, synchronous belt drive, magnetic grid ruler length, using numerical control system control; Blanking size, blanking size change fast, easy to achieve automatic production ☆Numerical control system, can complete the profile of different sizes of automatic blanking☆ Two saw heads can automatically convert the Angle to achieve the Angle cutting of 90° profile☆ Imported carbide saw blade, high precision, high durability☆ Imported linear bearing motion pair, so that the working accuracy is

Contact Now

4 Axis CNC Gantry Machining CenterModel:LGS-CNC-7000Feature:This kind of high speed 4 axis cnc machining center is suitable for milling all kinds of holes and slots of aluminum curtain wall or industrial aluminum profiles.Suitable for profile mounting holes, flow flume, lock holes, shaped holes, end milling and other processing processes gantry frame structure: more stable operation.With 3D programming software, it can perfectly realize drilling and milling.Adopt original imported control system, servo motor, with high quality ball screw, linear guide pair and bearing and other mechanisms

Contact Now

Mainly used for cutting industrial aluminum profiles, broken bridge aluminum doors and windows, curtain wall materials, and also used for cutting and blanking PVC and wood profiles.The machine adopts numerical control technology, and can complete automatic positioning, cutting and blanking of profiles with different specifications and sizes.High-quality carbide saw blades for aluminum materials are selected, with an outer diameter of 500, high linear speed and high machining accuracy.Numerical control transmission adopts high standard gear rack, with high transmission precision, accurate posit

Contact Now

CNC Any Angle Cutting Saw Model:LJZA-650Suitable for cutting sections of 0-330mm, with a wide range of applications.Carbide saw blade, high processing precision and high durability.Can be used with digital display/CNC <optional> fixed-length table for high processing efficiency.Can achieve simultaneous cutting of multiple profiles <90°>CNC Single Head Any Angle Cutting Saw Machine SpecificationPower supply380V/50HzCutting Width:45° max 200mm,90° max300mmMotor speed2840r/minCutting height:max 215mmMotor Power3*1kwSaw Blade Specification::Φ600*4*Φ30 Z144Working pressure0.5~0.8MpaAir

Contact Now

SHLJ-100Used for all kinds of aluminum alloy transmission box, hand lock, milling and one-time forming.Adopt double shaft combined cutting, special equipment for hand lock of transmission box.Automatic spray cooling tool, improve tool life.A clamping can be completed profiles perpendicular to each other in the two sides of the hole.The upper slot is formed by a single cutting with a professional cutter, and the length of the slot can be adjusted at will.Power supply380V/50HzTotal motor power1.5kW+2.2kWAir consumption2L/minOperating pressure0.6~0.8MPaMotor shaft diameterФ12mmNumber of mil

Contact Now

Feature1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

The moving part adopts high-precision linear guide rail pair, which runs stably and ensures the machining accuracy.Imported high-quality control system ensures stable and reliable operation of equipment.Imported motor is directly connected to saw blade, which has stable cutting and high machining precision.Equipped with multi-station capacity follow-up tool magazine, fully enclosed shell design and multiple safety protection structures to ensure the safety of operators.Power supply380V/50HzMotor speed2800r/minTotal power11kWWorking pressure0.6~0.8MpAAir supply50L/minCutting length300~6500mm&nb

Contact Now

Full automatic aluminum CNC cutting machineModel:SETHQG3Z-CNC-550Power: 380v 50HzMotor power: 4kw (frequency conversion)Motor speed: 2000-4500r/min (variable frequency speed regulation)Working air pressure: 0.6 ~ 0.8MPaAutomatic feeding length: 5 ~ 3000mmCutting width: 420 mmCutting height: 150mmSawing length: No limit when selecting manualSaw blade feed speed: 0-3m/min (private feed)Saw blade specification: ø550×ø30×3.8×Z120Cutting surface flatness: ≤0.01mmCutting profile perpendicularity: ≤0.05mmCutting surface roughness: Ra12.5μmRepeatable length accuracy: ≤ 0.05mmDimensions: 11200mm×1600mm

Contact Now

Uses for milling all kinds of holes and slots of aluminum doors, windows and curtain walls or industrial aluminum profiles, and can perfectly realize drilling and milling with 3D programming software.Imported control system, servo motor, high-quality ball screw, linear guide pair and bearing are adopted to ensure high machining accuracy of the equipment.The fixture position can be placed automatically.Double worktable can process two or two profiles at the same time, with interactive feeding and non-interference.With 12-station tool magazine, automatic tool change.Adopt high-speed

Contact Now

LJZ2-CNS-500*4300The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The machine head can rotate automatically, position and clamp in two directions, and can work independently with a single machine head.Automatic opening and closing of protective cover makes operation safer.The saw blade automatically swings at an angle of 45° and 90° , and

Contact Now