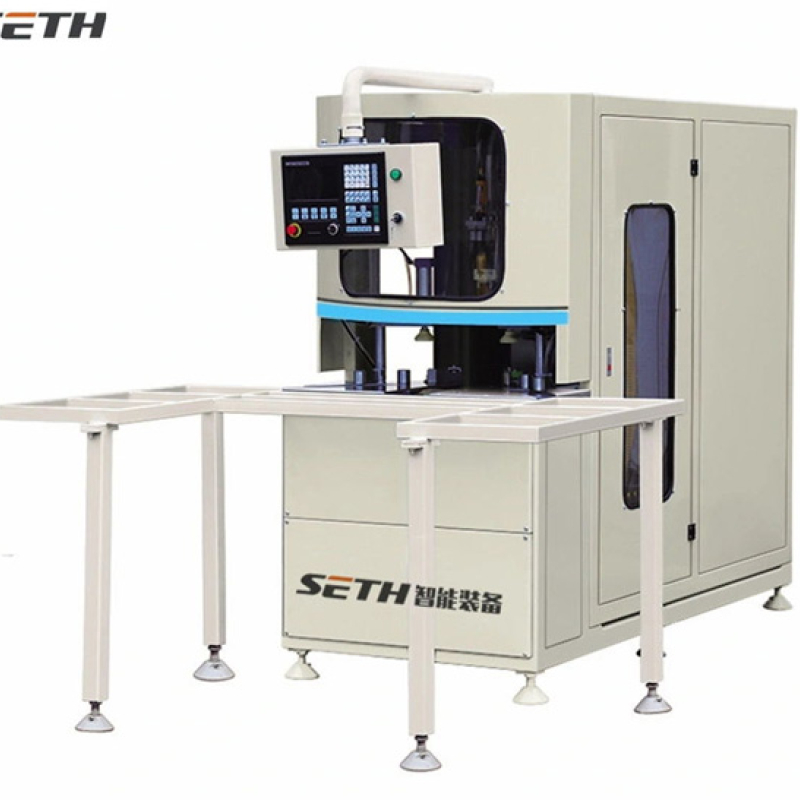

LXCA-60It is suitable for cleaning the welding corner joints of plastic doors and windows, with two-axis numerical control system and servo drive.The unique internal positioning method ensures the accuracy of cleaning the welds of doors and windows.It can store processing programs of profiles of various specifications.It can realize arc difference compensation and diagonal difference compensation, and can ideally meet the needs of making high-quality doors and windows with various section profiles.Power supply380V/50HzRating power1.4kWMilling cutter rotary speed2800r/minAir consumption80L/minP

Contact Now

Equipment advantages:● Used for cleansing welding corners of plastic doorways and Windows.● Two axis CNC system.● Servo power system, NUMERICAL manage system, solenoid valve, triplet and different foremost additives are imported well-known logo products, dependable performance, lengthy provider life.● Unique inner positioning, to make certain the accuracy of the door and window weld cleansing.● Can store a variety of specifications of the processing procedures.● Can realize the arc difference and oblique difference, can ideally meet the needs of all kinds of section profiles to make high-quali

Contact Now

Equipment advantages:● Used for cleaning welding corners of plastic doors and Windows.● Two axis CNC system.● Servo drive system, NUMERICAL control system, solenoid valve, triplet and other main components are imported famous brand products, reliable performance, long service life.● Unique internal positioning, to ensure the accuracy of the door and window weld cleaning.● Can store a variety of specifications of the processing procedures.● Can realize the arc difference and oblique difference, can ideally meet the needs of all kinds of section profiles to make high-quality doors and Windows.●

Contact Now

Unique internal positioning, to ensure the accuracy of the door and window weld cleaning.● Can store a variety of specifications of the processing procedures.● Can realize the arc difference and oblique difference, can ideally meet the needs of all kinds of section profiles to make high-quality doors and Windows.● Color LCD display Chinese operation interface simple and intuitive operation electronic disk storage space can be stored at the same time more than 200 profile surface processing procedures● Can be customized according to different profile section of different forces, to meet the req

Contact Now

Gadget benefits:● used for cleaning welding corners of plastic doorways and domestic windows.● axis cnc system.● servo pressure machine, numerical control device, solenoid valve, triplet and distinct vital components are imported famous emblem products, dependable normal performance, lengthy service life.● unique internal positioning, to ensure the accuracy of the door and window weld cleaning.● can hold a variety of specifications of the processing procedures.● Can realize the arc difference and oblique difference, can ideally meet the needs of all kinds of section profiles to make high

Contact Now

SHWA4-120*4500Used for welding color plastic, plastic steel profiles, welding is completed at the same time will be on both sides of the welding tumor cleaning is completed.

Contact Now

LMB-120It is suitable for angle-code punching and riveting connection of aluminum doors and windows.

Contact Now

1.It is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

LMB-SZ-120ZIt is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

LMB-SZ-120ZIt is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

LXCA-60Used for processing various types of drainage grooves and air pressure balance grooves of PVC Profile.Automatic tool changing for the under machine head, a clamping automatic complete the processing of profiles on both ends of the tank.Independent milling feeding system, no need of special maintenance, easy operation.Convenient adjustment of tool position, is suitable for different profiles.Water slot milling length adjustable within 100mm, wide adaptability.Power supply380V/50HzRating power2.2kWMotor rotary speed2800r/minCutting Width120mmCutting height20~60mmCutting length300~1700mmOv

Contact Now

Power Supply380V/50HzTotal Motor Power1.5kwOperating Pressure0.6~0.8MPaAir consumption3L/MinRated pressure15MpaExtrusion pressure85mmAdjusting Rang of Front Positioning54mmHeight of Machined Profile90mmWeight340kgOverall Dimension1000*1200*1200

Contact Now

1,Special designed for welding color PVC profile, no need corner clearance after welding. 2,Adopt programmable logic controller (PLC) ensures the machine running more stable and reliable. 3,Double pressing function ensures higher welding strength. 4,The pressure of front and back clamper is adjusted separately, so as to improve the planeness of the welding corner 5,The heads are operated individually, together. 6,No. 2,3,4 head can move horizontally, so that realize various kinds of welding combination.

Contact Now

Technical Parameter:Ø Input voltage380V/50HzØ Input power4.5KwØ Air pressure0.6~0.8MpaØ Air consumption280L/minØ Welding height25~100/120mmØ Welding width120mmØ Welding range400~4500mmØ Overall dimension5260X980X1760mm

Contact Now

Feature1. used for 45 ° glass glazing bead reducing and the attitude milling and decreasing.2. one time could slicing portions of glass glazing bead.3. with degree rulers, it could processing the glazing bead in keeping with the desired length with a purpose to ensure the precision of the processing length and remove the fan frame assembly mistakes.4. four portions noticed blade make certain specific lowering, double decreasing one every surrender to mill the hook foot.5.

Contact Now

The machine is made up of 2 machine heads, machine frame, electric control tank and material supporting fame etc.Can weld and clean the corner at one time. Specially for the colored profile.There are fixing mechanism, pressing mechanism, heating mechanism and head box etc.

Contact Now

It is mainly used for cutting industrial aluminum profiles, broken bridge aluminum doors and windows, curtain wall materials, and also for cutting PVC and wood profiles.

Contact Now

The shifting component adopts excessive-precision linear manual rail pair, which runs stably and guarantees the machining accuracy.Imported brilliant manage machine guarantees solid and dependable operation of equipment.Imported motor is immediately related to noticed blade, which has solid reducing and excessive machining precision.Equipped with multi-station capacity follow-up tool magazine, fully enclosed shell design and multiple safety protection structures to ensure the safety of operators.Power supply380V/50HzMotor speed2800r/minTotal power11kWWorking pressure0.6~0.8MpAAir supply50L/min

Contact Now

1,Special designed for welding color PVC profile, no need corner clearance after welding. 2,Adopt programmable logic controller (PLC) ensures the machine running more stable and reliable. 3,Double pressing function ensures higher welding strength. 4,The pressure of front and back clamper is adjusted separately, so as to improve the planeness of the welding corner 5,The heads are operated individually, together. 6,No. 2,3,4 head can move horizontally, so that realize various kinds of welding combination.

Contact Now

LJVW-60It is suitable for cutting 90°V-shaped grooves of aluminum-plastic profiles.Automatic central positioning device for easy operation.Pneumatic transmission is easy to operate.The mechanism design of the whole machine is reasonable and the operation is safe and convenient.Power supply380V/50HzRating power2.2kWMotor rotary speed2800r/minCutting Width120mmCutting height20~60mmCutting length300~1700mmOverall dimension1350×600×1350mmWeightAbout 200kg

Contact Now

LJJA-450SThis machine is used for cutting and blanking aluminum door and window corner profiles, with simple operation, reliable performance, advanced technology and easy maintenance.The cutting tool adopts cemented carbide saw blade, which has high cutting speed, high productivity and high machining precision.The feed motion pair adopts linear motion bearing, which has small motion resistance and high precision.The feeding mechanism adopts automatic feeding system, which is stable and reliable with high efficiency.With high automation, the advance and retreat of clamping and sawing are contro

Contact Now

● Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.● Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.● High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.● Supports multiple data import modes:Internet, LAN, U disk, Bluetooth, manual input, etc.

Contact Now

The system is made up of 2 system heads, device frame, electric powered control tank and cloth supporting fame etc.Can weld and easy the corner at one time. mainly for the coloured profile.There are fixing mechanism, urgent mechanism, heating mechanism and head box and many others.

Contact Now

☆ Mainly used for cutting industrial aluminum profiles, aluminum doors and Windows, curtain wall materials, also can be used for PVC and woodCutting and blanking of profiles.☆ The machine adopts numerical control technology and can complete automatic positioning cutting of different sizes of profiles.☆ Selected high-quality aluminum carbide saw blade, outer diameter up to 500, high wire speed, high processing accuracy.☆ CNC transmission adopts high standard rack and pinion, high transmission accuracy, accurate positioning, stable work.☆ High precision spindle ensures stable rotation of saw bla

Contact Now