LJXG-300*150Used for copying all kinds of holes, tenons and grooves, running water troughs, etc.

Contact Now

LXFG2-270*115It is suitable for copying all kinds of holes, tenons and grooves, running water troughs, etc.

Contact Now

Aluminum Door Making Machine Copy Routing Drilling MachineCopy Routing Drilling Machine Model:LJXG-300*200Precision machining of linear guide rail makes the milling cutter move stably and flexibly and operate easily.The advanced milling cutter chuck is selected to match with the imported air-cooled integrated electricspindle, which makes the milling cutter clamping simple and convenient.Excellent air-oil filter atomization cooling system makes milling effect better. Copy Routing Drilling Machine SpecificationPower supply380V/50HzMotor2.2kWMotor speed18000r/mi

Contact Now

LZK-CNC-150Such as the center stile of aluminum-plastic profiles and various holes of louvers.Numerical control system control, simple operation, accurate processing and high efficiency.This machine replaces many complicated processes such as manual marking and pistol drilling, and improves the machining quality and work efficiency several times.Drilling about 600 square meters every day greatly reduces the labor intensity of workers, and the drilling spacing and speed can be adjusted at will, so it is suitable for various profiles.Power supply380V/50HzMotor power2×1.5kWOperation air pressure0

Contact Now

LZZ6G-13It is suitable for drilling aluminum alloy doors, windows and curtain wall profiles, especially for long materials and mass production.The section is less than 200*200mm, and the processing length can reach 6000mm.Equipped with six sets of drilling heads to meet the requirement of simultaneous processing of multiple groups of holes.The display screen displays machining data in real time, which is intuitive and clear, and effectively reduces human error.The feeding adopts air c

Contact Now

LJLKZ-2300It is suitable for high-efficiency drilling of hinge mounting holes, sliding support wind support holes and four-link holes of aluminum doors and windows (external windows, overhead windows, etc.).Four holes can be drilled on both sides at the same time, so the production efficiency is high, and the two heads can work independently or simultaneously.The bed of the machine tool is equipped with two heads, the left head is fixed and fixed on the bed with screws; The right head can be pulled by the handle to move on the circular guide rail and locked at the requi

Contact Now

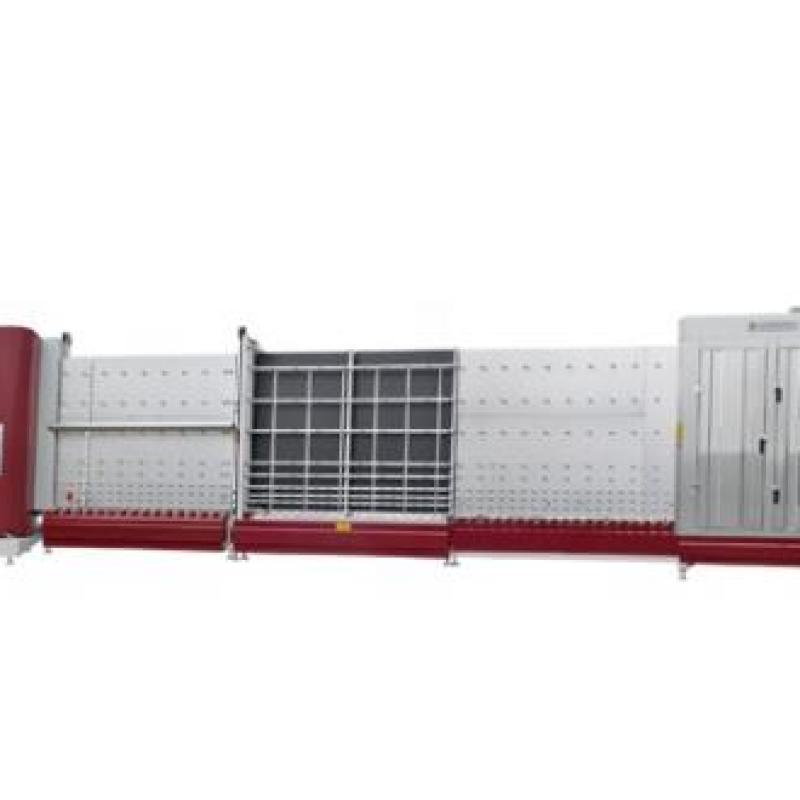

Italy Technical level of Production ,Installation and Mechanical.Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass --- two or three pieces of glass or different sizes of glass .it adjust the size of different glass by servo motor to realize high auto and more exact running.More practical and convenient design of pressing part about vacuum , pneumatic driving.

Contact Now

1.Gantry cnc machining center adopt the original imported control system, servo motor, with high-quality ball screw, linear guide and bearing and other mechanisms to ensure that the equipment has a high machining accuracy. The position of the fixture can be automatically placed.2. Double table can simultaneously carry out two pieces or two kinds of profile processing, interactive feeding, non-interference.With 12 station tool library, automatic tool change.3.

Contact Now

Aluminum Door Making Machine CNC Drilling Milling MachineCNC Drilling Milling Machine Model:DSK-CNC-3500This machine is a CNC machining center for heavy aluminum profiles,suitable for high speed machiningof thick and thin wall profiles.The design target of the whole cnc drilling milling machine is high speed and high precision machining.The structure design and power ratio of the whole machine are strengthened,so that the equipment has high strength bed and moving parts,and the service efficiency is greatly improved.Our cnc drilling milling machine adopt high speed and high pre

Contact Now

Adopt Taiwan SYNTEC CNC control system. Have professional CADCAM programming software. It can transform processing G code automatically, have the function of easy operation, high efficiency and lower labor intensity.Imported guide rail, sliding block, X axis adopt high precision oblique gear and rack driving.

Contact Now

Aluminum Door Making Machine CNC Drilling Milling MachineModel:SKX3+1-CNC-1200Features:☆ spindle adopts air-cooled spindle, power 6 kw, speed 0~18000 rpm, high precision, good safety and high reliability.☆ adopt CNC numerical control system. Equipped with professional CAD-CAM programming software.

Contact Now

Aluminum Door Making Machine CNC Drilling Milling Machine CNC DRILLING MILLING MACHINE SKX4-CNC-1500☆ spindle adopts air-cooled spindle, power 6 kw, speed 0~18000 rpm, high precision, good safety andhigh reliability.☆ adopt CNC numerical control system.

Contact Now

Uses for milling all kinds of holes and slots of aluminum doors, windows and curtain walls or industrial aluminum profiles, and can perfectly realize drilling and milling with 3D programming software.Imported control system, servo motor, high-quality ball screw, linear guide pair and bearing are adopted to ensure high machining accuracy of the equipment.The fixture position can be placed automatically.Double worktable can process two or two profiles at the same time, with interactive feeding and non-interference.With 12-station tool magazine, automatic tool change.Adopt high-speed

Contact Now

This machine is a CNC machining center for heavy aluminum profiles, suitable for high speed machining of thick and thin wall profiles.The design target of the whole machine is high-speed and high- precision machining.

Contact Now

cnc drilling milling machine for aluminum profileCNC MILLERPower supply380V 50HzTotal power10.5 KwMain shaft powerS1:3.5kwWorking pressure0.6~0.8 MPaMaximum speedrpm 18000X axis travel1500mm Y axis travel500mm Z axis travel350 mmX axis velocity50000 mm/minY axis, Z axis velocity15,000 mm/minDimensions2380x2000x2200mm WeightAbout 900 kg

Contact Now

Adopt CNC numerical control system. Equipped with professional CAD- CAM programming software. Automatic conversion and processing of G code, simple operation, high efficiency and low labor intensity.All the kinematic pairs adopt imported guide rails and sliders, the X axis adopts high-precision helical gears and helical racks for transmission, and the Y axis and Z axis adopt high-precision ball wire shoulder transmission. The transmission is stable and the precision of the whole machine is effectively improved.The workbench is turned over 180°. -90° ~ 0° ~+90°.

Contact Now

1CNC machining center for heavy industrial aluminum profiles,suitable for high speed machining of thick and thin curtain wall profiles.2The design target of the whole machine is high-speed and highprecision machining.3The structure design and power ratio of the whole machine are strengthened, so that the equipment has high-strength bed and moving parts, and the service efficiency is greatly improved.4 Adopt high speed and high precision motorized spindle.X axis adopts high precision helical gear and rack, Y axis and Z axis adopt high precision ball screw drive.5 Tool design

Contact Now

1.X axis high-precision helical gear and rack drive,Y axis, Z axis using high-precision ball screw drive, smooth running, high precision2, Turn over the beam with the square rail, with the tightening module, easy adjustment3· Table flip 180".

Contact Now

1.The design goal of the machine is high speed and high precision machining, and the structure design and power ratio of the machine are carried outEnhanced, so that the equipment has a high strength bed and moving parts, the use of efficiency has been greatly improved.2. Wide range of processing width and processing height to meet the processing of variety of profiles.Adopt high speed and high precision motorized spindle. X axis adopts high precision helical gear and helical rack, Y axis and Z axis adopts high precision ball screw drive.3.

Contact Now

Numerical control transmission adopts high standard gear rack, with high transmission precision, accurate positioning and stable operation.The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The machine head can rotate automatically, position and clamp in two directions, and can work independently with a single machine head.Automatically opening and closing the protective cover,Make the operati

Contact Now

LJZ2Z-CNC-550*4300Using cemented carbide saw blade, the outer diameter can reach 550,the linear speed is high, and the machining precision is high.High transmission precision, accurate positioning and stable operation.High precision spindle motor makes the saw blade rotate stably.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.When the machine works, the saw blades with two saw heads can cut at the same time or separately.The machine head is fixed at an angle of 45° to ensure stable precision in long-te

Contact Now

LJZ2-CNS-500*4300The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The machine head can rotate automatically, position and clamp in two directions, and can work independently with a single machine head.Automatic opening and closing of protective cover makes operation safer.The saw blade automatically swings at an angle of 45° and 90° , and

Contact Now

600mm saw blade arbitrary Angle CNC double mitre sawFeature:Mainly used for industrial aluminum profiles, aluminum doors and Windows, curtain wall material cutting.Widely used in automotive, shipbuilding, locomotive, machine tools, molds and other mechanical equipment manufacturing field of precision parts CNC processing, machine tools with high precision, high speed characteristics, can achieve high-speed cutting.The imported high-speed spindle direct connected motor is mounted with diamond saw blade.

Contact Now

1.This machine is designed for processing round holes, slots, keyhole etc on aluminum profile, window-door and curtain wall industry, it is also suitable for processing milling, chamfering,engraving plane surface and other procedure.2. Main spindle adopt air-cooling electric main axis, 3kW power, 0~18000r/min , have the function of high precision, high safety and high reliable.3.Adopt Taiwan SYNTEC CNC control system. Have professional CAD CAM programming software.

Contact Now