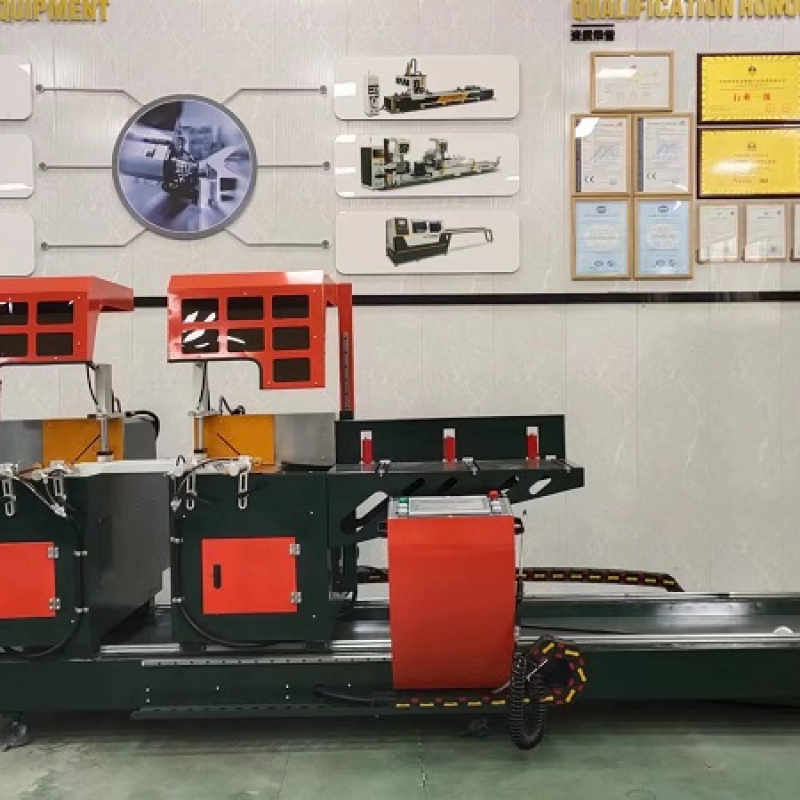

Feature1. used for 45 ° glass glazing bead reducing and the attitude milling and decreasing.2. one time could slicing portions of glass glazing bead.3. with degree rulers, it could processing the glazing bead in keeping with the desired length with a purpose to ensure the precision of the processing length and remove the fan frame assembly mistakes.4. four portions noticed blade make certain specific lowering, double decreasing one every surrender to mill the hook foot.5.

Contact Now

Feature1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

Feature1. used for 45 ° glass glazing bead lowering and the mindset milling and decreasing.2. one time ought to slicing quantities of glass glazing bead.3. with diploma rulers, it is able to processing the glazing bead in step with the favored period a good way to make sure the precision of the processing period and eliminate the fan body meeting mistakes.4. four portions noticed blade make certain specific lowering, double decreasing one every surrender to mill the hook foot.5.

Contact Now

1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

1. used for 45° glass glazing bead slicing and the angle milling and reducing.2. one time could slicing pieces of glass glazing bead.3. with measure rulers, it could processing the glazing bead in keeping with the wanted size with a view to make certain the precision of the processing size and do away with the fan body assembly blunders.4. 4 pieces noticed blade make certain unique reducing, double reducing one every give up to mill the hook foot.5.

Contact Now

1. used for 45° glass glazing bead cutting and the perspective milling and lowering.2. one time ought to cutting portions of glass glazing bead.3. with degree rulers, it can processing the glazing bead consistent with the desired length as a way to ensure the precision of the processing length and cast off the fan frame meeting blunders.4. four portions observed blade ensure specific lowering, double lowering one each surrender to mill the hook foot.5.

Contact Now

LJVW-60It is suitable for cutting 90°V-shaped grooves of aluminum-plastic profiles.Automatic central positioning device for easy operation.Pneumatic transmission is easy to operate.The mechanism design of the whole machine is reasonable and the operation is safe and convenient.Power supply380V/50HzRating power2.2kWMotor rotary speed2800r/minCutting Width120mmCutting height20~60mmCutting length300~1700mmOverall dimension1350×600×1350mmWeightAbout 200kg

Contact Now

LJZ2-CNS-450*3700AHigh precision spindle makes the saw blade rotate stably.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device to save the processing cost of doors and windows (alternative).When the machine works, the saw blades with two saw heads can cut at the same time or separately.With the saw blade from back to front, the sawing profile is safer and more reliable, and the sawing height and width are very large.The saw blade can automatically swing to the

Contact Now

LXCA-60Used for processing various types of drainage grooves and air pressure balance grooves of PVC Profile.Automatic tool changing for the under machine head, a clamping automatic complete the processing of profiles on both ends of the tank.Independent milling feeding system, no need of special maintenance, easy operation.Convenient adjustment of tool position, is suitable for different profiles.Water slot milling length adjustable within 100mm, wide adaptability.Power supply380V/50HzRating power2.2kWMotor rotary speed2800r/minCutting Width120mmCutting height20~60mmCutting length300~1700mmOv

Contact Now

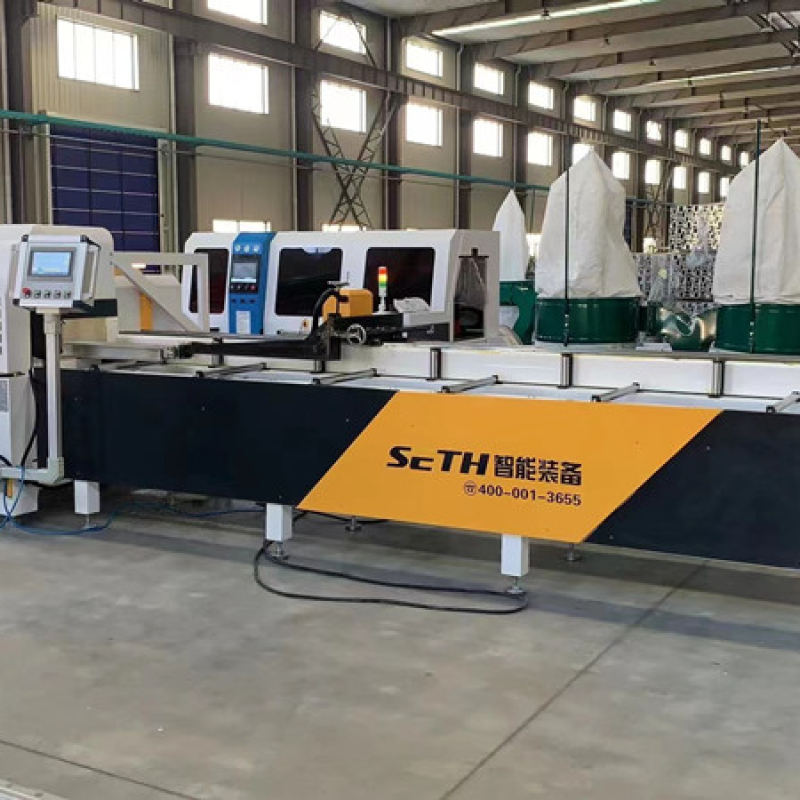

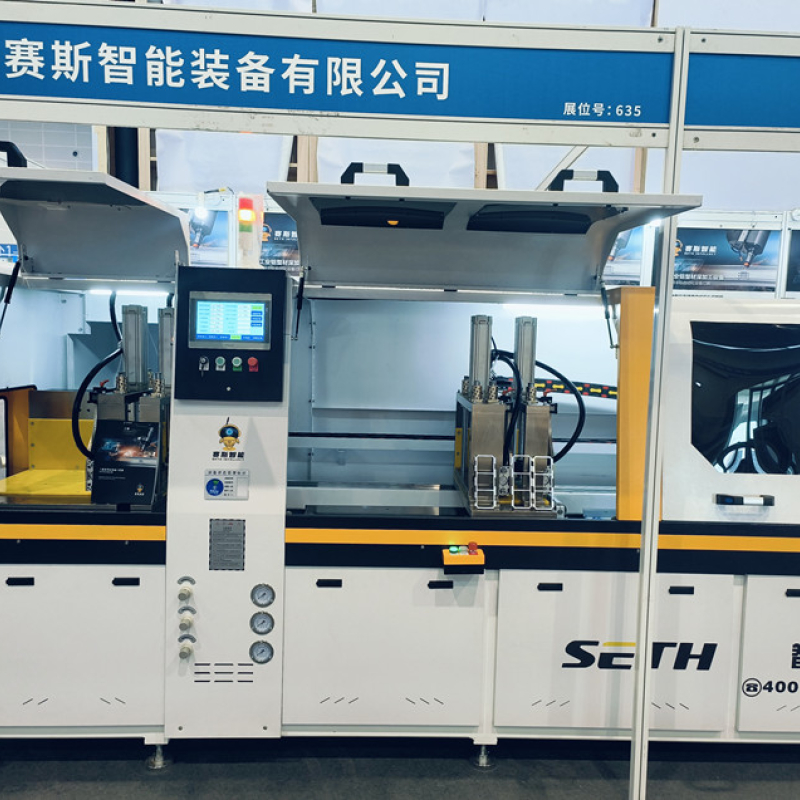

Features of equipment:Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.● Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.● High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.● Supports multiple data import modes:Internet, LAN, U disk, Bluetooth, manual input, etc.

Contact Now

Mainly used for cutting industrial aluminum profiles, broken bridge aluminum doors and windows, curtain wall materials, and also used for cutting and blanking PVC and wood profiles.The machine adopts numerical control technology, and can complete automatic positioning, cutting and blanking of profiles with different specifications and sizes.High-quality carbide saw blades for aluminum materials are selected, with an outer diameter of 500, high linear speed and high machining accuracy.Numerical control transmission adopts high standard gear rack, with high transmission precision, accurate posit

Contact Now

It is mainly used for cutting industrial aluminum profiles, broken bridge aluminum doors and windows, curtain wall materials, and also for cutting PVC and wood profiles.

Contact Now

Feature1.Used for mullion cutting when PVC window adopt the welding technology.2. 2 saw blades are settled as 90° so that can realize two V shape cutting by one time clamping. High precision and efficiency3. Patent technology to prevent collapse cutting precede.4. Easily adjustable depth, and adjustable stable feeding speed.5. Automatic crossing cutting two mullion end in one time. Save profile cost and improve efficiency. Support arm ensure cutting precision.6. Special clamping device ensure safety operation.

Contact Now

Feature1.Used for mullion cutting when PVC window adopt the welding technology.2. 2 saw blades are settled as 90° so that can realize two V shape cutting by one time clamping. High precision and efficiency3. Patent technology to prevent collapse cutting precede.4. Easily adjustable depth, and adjustable stable feeding speed.5. Automatic crossing cutting two mullion end in one time. Save profile cost and improve efficiency. Support arm ensure cutting precision.6. Special clamping device ensure safety operation.

Contact Now

The shifting component adopts excessive-precision linear manual rail pair, which runs stably and guarantees the machining accuracy.Imported brilliant manage machine guarantees solid and dependable operation of equipment.Imported motor is immediately related to noticed blade, which has solid reducing and excessive machining precision.Equipped with multi-station capacity follow-up tool magazine, fully enclosed shell design and multiple safety protection structures to ensure the safety of operators.Power supply380V/50HzMotor speed2800r/minTotal power11kWWorking pressure0.6~0.8MpAAir supply50L/min

Contact Now

LJJA-CNC-500The cutting tool adopts cemented carbide saw blade, which has high cutting speed, high productivity and high machining precision.The feed motion pair adopts linear motion bearing, which has small motion resistance and high precision.The feeding mechanism adopts automatic feeding system, which is stable and reliable with high efficiency.With high automation, the advance and retreat of clamping and sawing are controlled by pneumatic system, which is safe and reliable.It has automatic counting function and no cutting function of tailings.Continuous cutting of 6-meter angle profile can

Contact Now

● Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.● Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.● High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.● Supports multiple data import modes:Internet, LAN, U disk, Bluetooth, manual input, etc.

Contact Now

Feature1.Used for mullion cutting when PVC window adopt the welding technology.2. 2 saw blades are settled as 90° so that can realize two V shape cutting by one time clamping. High precision and efficiency3. Patent technology to prevent collapse cutting precede.4. Easily adjustable depth, and adjustable stable feeding speed.5. Automatic crossing cutting two mullion end in one time. Save profile cost and improve efficiency. Support arm ensure cutting precision.6. Special clamping device ensure safety operation.

Contact Now

LJB2B-CNC-500*6000The cutting angle is auto adjustable through the imported servo motor between 45° to 157.5° Imported control system can accomplish cutting optimization.Several profile processing dimensions can be input in one time andmake continuous cutting.The processing dimension can be directly input, the cutting length can be changed without returning the reference point.The airproof device under the worktable has wonderful crumbs- clearing effect.The following saw cover keeps it working in the clean environment.The profile is clamped by two cylinders in every head, and kept the cutting

Contact Now

LJZ2-CNC-600*4300High-quality cemented carbide saw blades for aluminum materials areselected, with high linear speed and high machining accuracy.Numerical control transmission adopts high standard gear rack, with high transmission precision, accurate positioning and stable operation.The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The saw blade automatically swings at an angle of 45° and 90°

Contact Now

☆ Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.☆ Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.☆ High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated air-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.☆ Supports multiple data import modes:Internet, LAN, U di

Contact Now

LJLY-CNC-350It is suitable for 90° precision cutting process of aluminum alloy glass wire pressing profile, and is suitable for mass continuous production.Bluetooth transmission is adopted, which is accurate and does not need secondary modification.Equipped with tool detection system to improve service life.Equipped with wireless hand-held transmission system, automatic material reduction function.The standard coding function is convenient for customers to use the material type without making mistakes, thus improving the utiliza

Contact Now

600mm saw blade Arbitrary angle CNC double mitre saw for aluminum profileModel: LJB2B-CNC-600*6000Feature:Mainly used for industrial aluminum profiles, aluminum doors and Windows, curtain wall material cutting, can also be used cutting of PVC and wood profiles. The imported high-speed spindle direct connected motor is mounted with diamond saw blade.

Contact Now

LJZ2-CNS-500*4300The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The machine head can rotate automatically, position and clamp in two directions, and can work independently with a single machine head.Automatic opening and closing of protective cover makes operation safer.The saw blade automatically swings at an angle of 45° and 90° , and

Contact Now