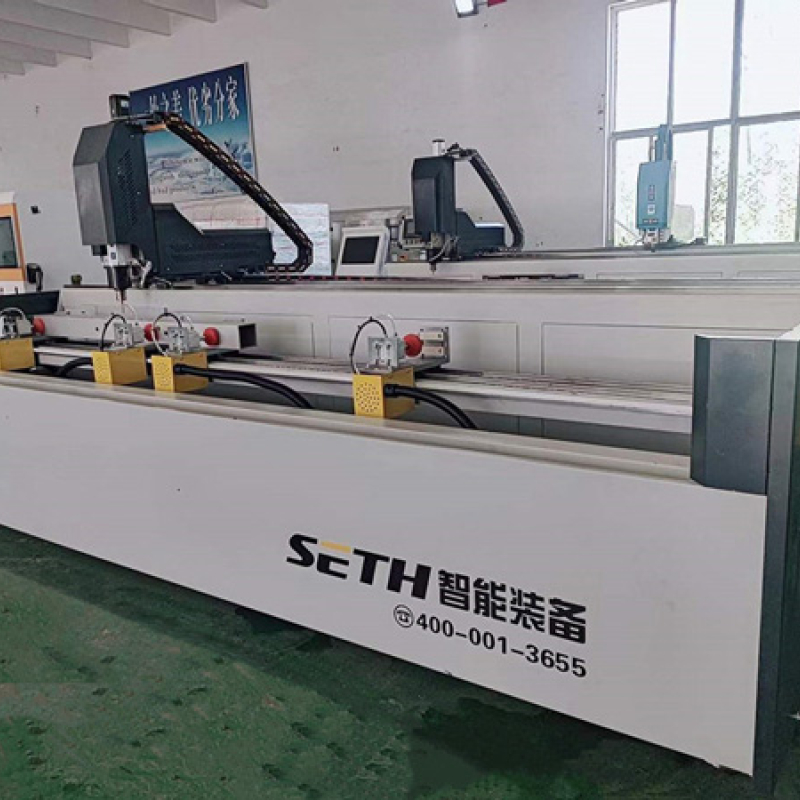

This machine is a CNC machining center for heavy aluminum profiles, suitable for high speed machining of thick and thin wall profiles.The design target of the whole machine is high-speed and high- precision machining.

Contact Now

1.X axis high-precision helical gear and rack drive,Y axis, Z axis using high-precision ball screw drive, smooth running, high precision2, Turn over the beam with the square rail, with the tightening module, easy adjustment3· Table flip 180".

Contact Now

3 axis CNC Machining Center for Aluminum ProfileModel:DSK-CNC-3500Equipment features:● This model for the system door and window intelligent connection model, support ERP MES management software door and window software docking, to achieve the integration of production and marketing control to improve production efficiency.● Scanning sawing two-dimensional code system automatically generates round holes, slot holes, keyholes, special-shaped holes, milling, chamfering, and other processes without manual participation to reduce manual labor intensity and improve the qualified rat

Contact Now

The shifting component adopts excessive-precision linear manual rail pair, which runs stably and guarantees the machining accuracy.Imported brilliant manage machine guarantees solid and dependable operation of equipment.Imported motor is immediately related to noticed blade, which has solid reducing and excessive machining precision.Equipped with multi-station capacity follow-up tool magazine, fully enclosed shell design and multiple safety protection structures to ensure the safety of operators.Power supply380V/50HzMotor speed2800r/minTotal power11kWWorking pressure0.6~0.8MpAAir supply50L/min

Contact Now

LZK-CNC-150Such as the center stile of aluminum-plastic profiles and various holes of louvers.Numerical control system control, simple operation, accurate processing and high efficiency.This machine replaces many complicated processes such as manual marking and pistol drilling, and improves the machining quality and work efficiency several times.Drilling about 600 square meters every day greatly reduces the labor intensity of workers, and the drilling spacing and speed can be adjusted at will, so it is suitable for various profiles.Power supply380V/50HzMotor power2×1.5kWOperation air pressure0

Contact Now

1CNC machining center for heavy industrial aluminum profiles,suitable for high speed machining of thick and thin curtain wall profiles.2The design target of the whole machine is high-speed and highprecision machining.3The structure design and power ratio of the whole machine are strengthened, so that the equipment has high-strength bed and moving parts, and the service efficiency is greatly improved.4 Adopt high speed and high precision motorized spindle.X axis adopts high precision helical gear and rack, Y axis and Z axis adopt high precision ball screw drive.5 Tool design

Contact Now

Feature1. used for 45 ° glass glazing bead reducing and the attitude milling and decreasing.2. one time could slicing portions of glass glazing bead.3. with degree rulers, it could processing the glazing bead in keeping with the desired length with a purpose to ensure the precision of the processing length and remove the fan frame assembly mistakes.4. four portions noticed blade make certain specific lowering, double decreasing one every surrender to mill the hook foot.5.

Contact Now

1.Gantry cnc machining center adopt the original imported control system, servo motor, with high-quality ball screw, linear guide and bearing and other mechanisms to ensure that the equipment has a high machining accuracy. The position of the fixture can be automatically placed.2. Double table can simultaneously carry out two pieces or two kinds of profile processing, interactive feeding, non-interference.With 12 station tool library, automatic tool change.3.

Contact Now

LDXB5-CNC-250It is suitable for sawing and milling the tenons and step surfaces of the castellated profiles in aluminum doors and windows. It is controlled by 5-axis numerical control system, with simple programming, high compatibility, higher efficiency and reliability.Two sawing and milling motors are installed, one to realize horizontalmilling and the other to realize vertical longitudinal cutting, which gives consideration to the end milling operations of various cross-sections and strengthening the center stiles, and is more versatile.The angle of

Contact Now

1. used for 45° glass glazing bead slicing and the angle milling and reducing.2. one time could slicing pieces of glass glazing bead.3. with measure rulers, it could processing the glazing bead in keeping with the wanted size with a view to make certain the precision of the processing size and do away with the fan body assembly blunders.4. 4 pieces noticed blade make certain unique reducing, double reducing one every give up to mill the hook foot.5.

Contact Now

1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

Feature1. used for 45 ° glass glazing bead lowering and the mindset milling and decreasing.2. one time ought to slicing quantities of glass glazing bead.3. with diploma rulers, it is able to processing the glazing bead in step with the favored period a good way to make sure the precision of the processing period and eliminate the fan body meeting mistakes.4. four portions noticed blade make certain specific lowering, double decreasing one every surrender to mill the hook foot.5.

Contact Now

This gadget is a CNC machining middle for heavy aluminum profiles, appropriate for excessive pace machining of thick and skinny wall profiles.The layout goal of the complete gadget is excessive-pace and excessive- precision machining.

Contact Now

It is suitable for the molding of end faces, step faces and end grooves of various profiles, and can mill multiple profiles at the same time.High-power and high-precision spindle motor ensures machining power and precision.Automatic feeding, low labor intensity.The motor can be adjusted up and down, and it is quick and convenient to change knives.The cutting tool feed adopts straight square rail movement, which makes the working performance stable.Power supply380V/50HzTotal motor power2.2kWMotor speed2800r/minOperating pressure0.6~0.8MPaMotor shaft diameterФ32mmNumber of milling cutterФ250mmTo

Contact Now

4 Axis CNC Gantry Machining CenterModel:LGS-CNC-7000Feature:This kind of high speed 4 axis cnc machining center is suitable for milling all kinds of holes and slots of aluminum curtain wall or industrial aluminum profiles.Suitable for profile mounting holes, flow flume, lock holes, shaped holes, end milling and other processing processes gantry frame structure: more stable operation.With 3D programming software, it can perfectly realize drilling and milling.Adopt original imported control system, servo motor, with high quality ball screw, linear guide pair and bearing and other mechanisms

Contact Now

LJDX-BP-250*5It is suitable for milling the end face of aluminum profile, so as to meet the matching between center stile and frame material.

Contact Now

1. used for 45° glass glazing bead cutting and the perspective milling and lowering.2. one time ought to cutting portions of glass glazing bead.3. with degree rulers, it can processing the glazing bead consistent with the desired length as a way to ensure the precision of the processing length and cast off the fan frame meeting blunders.4. four portions observed blade ensure specific lowering, double lowering one each surrender to mill the hook foot.5.

Contact Now

The moving part adopts high-precision linear guide rail pair, which runs stably and ensures the machining accuracy.Imported high-quality control system ensures stable and reliable operation of equipment.Imported motor is directly connected to saw blade, which has stable cutting and high machining precision.Equipped with multi-station capacity follow-up tool magazine, fully enclosed shell design and multiple safety protection structures to ensure the safety of operators.Power supply380V/50HzMotor speed2800r/minTotal power11kWWorking pressure0.6~0.8MpAAir supply50L/minCutting length300~6500mm&nb

Contact Now

Adopt Taiwan SYNTEC CNC control system. Have professional CADCAM programming software. It can transform processing G code automatically, have the function of easy operation, high efficiency and lower labor intensity.Imported guide rail, sliding block, X axis adopt high precision oblique gear and rack driving.

Contact Now

Wide range of processing width and processing height to meet the processing of variety of profiles.Adopt high speed and high precision motorized spindle.

Contact Now

1.The design goal of the machine is high speed and high precision machining, and the structure design and power ratio of the machine are carried outEnhanced, so that the equipment has a high strength bed and moving parts, the use of efficiency has been greatly improved.2. Wide range of processing width and processing height to meet the processing of variety of profiles.Adopt high speed and high precision motorized spindle. X axis adopts high precision helical gear and helical rack, Y axis and Z axis adopts high precision ball screw drive.3.

Contact Now

Uses for milling all kinds of holes and slots of aluminum doors, windows and curtain walls or industrial aluminum profiles, and can perfectly realize drilling and milling with 3D programming software.Imported control system, servo motor, high-quality ball screw, linear guide pair and bearing are adopted to ensure high machining accuracy of the equipment.The fixture position can be placed automatically.Double worktable can process two or two profiles at the same time, with interactive feeding and non-interference.With 12-station tool magazine, automatic tool change.Adopt high-speed

Contact Now

power supply380V/50HzAir pressure0.5~0.8MPaTotal power6.0kWMain axis power8.5kWMax rotary speed18000r/minX-axis longitudinal travel1200mmY-axis transverse travel300mmZ-axis vertical travel280mmY-axis speed50m/minZ-axis speed15m/minOverall dimension2200×1600×1950mmWeight500kgs

Contact Now

Feature1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now