LJLY-CNC-350It is suitable for 90° precision cutting process of aluminum alloy glass wire pressing profile, and is suitable for mass continuous production.Bluetooth transmission is adopted, which is accurate and does not need secondary modification.Equipped with tool detection system to improve service life.Equipped with wireless hand-held transmission system, automatic material reduction function.The standard coding function is convenient for customers to use the material type without making mistakes, thus improving the utiliza

Contact Now

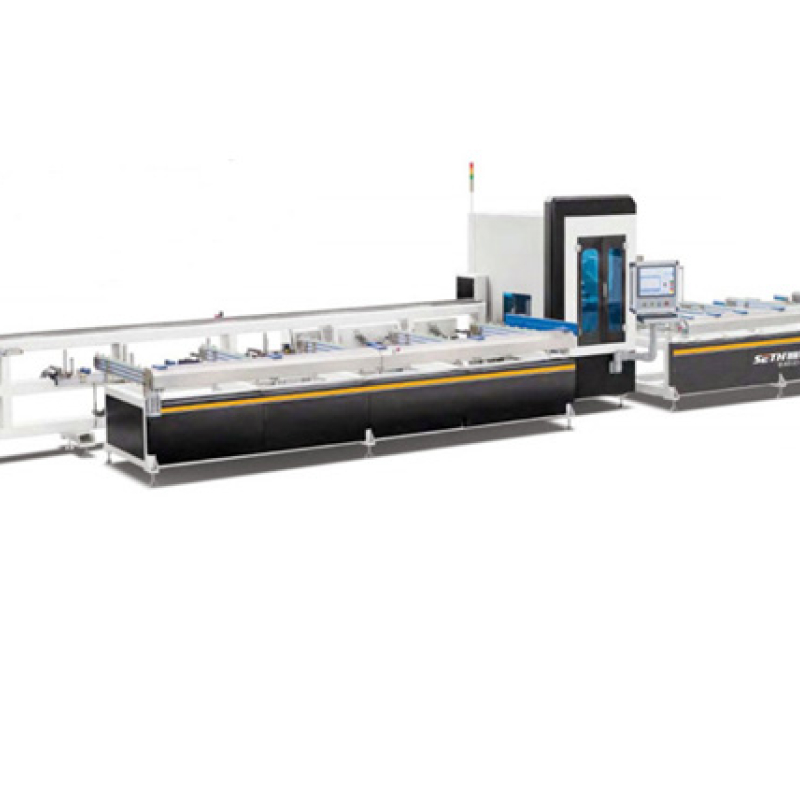

3 axis CNC Machining Center for Aluminum ProfileModel:DSK-CNC-3500Equipment features:● This model for the system door and window intelligent connection model, support ERP MES management software door and window software docking, to achieve the integration of production and marketing control to improve production efficiency.● Scanning sawing two-dimensional code system automatically generates round holes, slot holes, keyholes, special-shaped holes, milling, chamfering, and other processes without manual participation to reduce manual labor intensity and improve the qualified rat

Contact Now

The shifting component adopts excessive-precision linear manual rail pair, which runs stably and guarantees the machining accuracy.Imported brilliant manage machine guarantees solid and dependable operation of equipment.Imported motor is immediately related to noticed blade, which has solid reducing and excessive machining precision.Equipped with multi-station capacity follow-up tool magazine, fully enclosed shell design and multiple safety protection structures to ensure the safety of operators.Power supply380V/50HzMotor speed2800r/minTotal power11kWWorking pressure0.6~0.8MpAAir supply50L/min

Contact Now

LJDX-BP-250*5It is suitable for milling the end face of aluminum profile, so as to meet the matching between center stile and frame material.

Contact Now

The moving part adopts high-precision linear guide rail pair, which runs stably and ensures the machining accuracy.Imported high-quality control system ensures stable and reliable operation of equipment.Imported motor is directly connected to saw blade, which has stable cutting and high machining precision.Equipped with multi-station capacity follow-up tool magazine, fully enclosed shell design and multiple safety protection structures to ensure the safety of operators.Power supply380V/50HzMotor speed2800r/minTotal power11kWWorking pressure0.6~0.8MpAAir supply50L/minCutting length300~6500mm&nb

Contact Now

LDXB5-CNC-250It is suitable for sawing and milling the tenons and step surfaces of the castellated profiles in aluminum doors and windows. It is controlled by 5-axis numerical control system, with simple programming, high compatibility, higher efficiency and reliability.Two sawing and milling motors are installed, one to realize horizontalmilling and the other to realize vertical longitudinal cutting, which gives consideration to the end milling operations of various cross-sections and strengthening the center stiles, and is more versatile.The angle of

Contact Now

☆ especially used for slicing commercial aluminum profiles, aluminum doorways and domestic home windows, curtain wall substances, additionally may be used for percent and wood slicing and blanking of profiles.☆ the tool adopts numerical control technology and can complete automated positioning cutting of various sizes of profiles.☆ decided on awesome aluminum carbide saw blade, outer diameter as much as 500, high cord speed, high processing accuracy.☆ cnc transmission adopts immoderate popular rack and pinion, immoderate transmission accuracy, accurate positioning, stable artwork.☆ high precis

Contact Now

This machine is a CNC machining center for heavy aluminum profiles, suitable for high speed machining of thick and thin wall profiles.The design target of the whole machine is high-speed and high- precision machining.

Contact Now

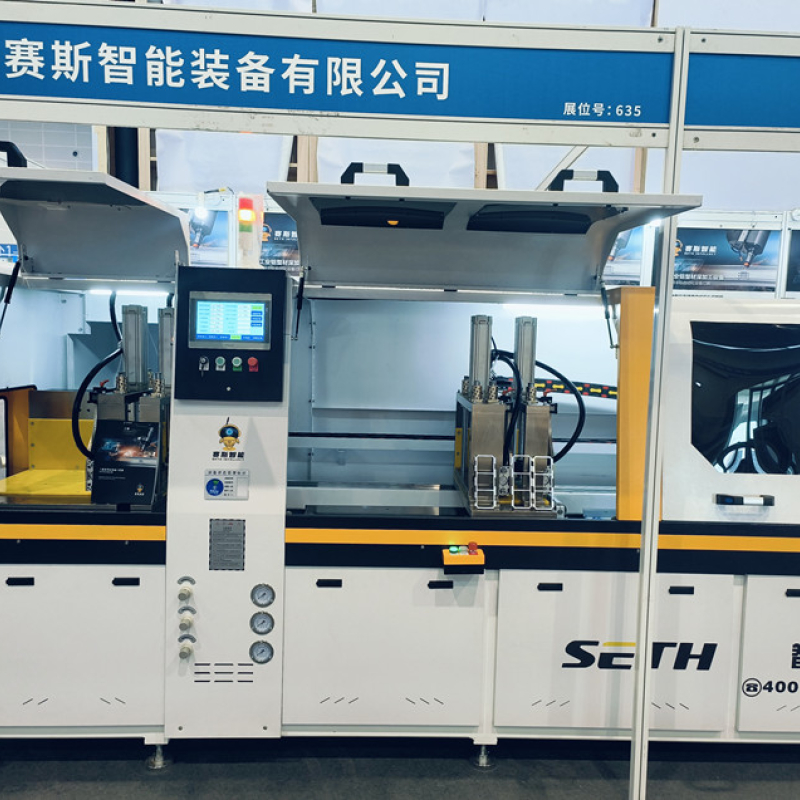

Features of equipment:Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.● Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.● High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.● Supports multiple data import modes:Internet, LAN, U disk, Bluetooth, manual input, etc.

Contact Now

LJJA-CNC-500AThe feed motion pair adopts linear motion bearing, which has small motion resistance and high precision.The feeding mechanism adopts automatic feeding system, which is stable and reliable with high efficiency.With high automation, the advance and retreat of clamping and sawing are controlled by pneumatic system, which is safe and reliable.It has automatic counting function and no cutting function of tailings.Continuous cutting of 6-meter angle profile can be realized only by clamping once.Automatically save the number of cut segments in case of power failure.Adopt micro spray cool

Contact Now

LJVW-60It is suitable for cutting 90°V-shaped grooves of aluminum-plastic profiles.Automatic central positioning device for easy operation.Pneumatic transmission is easy to operate.The mechanism design of the whole machine is reasonable and the operation is safe and convenient.Power supply380V/50HzRating power2.2kWMotor rotary speed2800r/minCutting Width120mmCutting height20~60mmCutting length300~1700mmOverall dimension1350×600×1350mmWeightAbout 200kg

Contact Now

● Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.● Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.● High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.● Supports multiple data import modes:Internet, LAN, U disk, Bluetooth, manual input, etc.

Contact Now

LJJA-CNC-500The cutting tool adopts cemented carbide saw blade, which has high cutting speed, high productivity and high machining precision.The feed motion pair adopts linear motion bearing, which has small motion resistance and high precision.The feeding mechanism adopts automatic feeding system, which is stable and reliable with high efficiency.With high automation, the advance and retreat of clamping and sawing are controlled by pneumatic system, which is safe and reliable.It has automatic counting function and no cutting function of tailings.Continuous cutting of 6-meter angle profile can

Contact Now

LJB2B-CNC-500*6000The cutting angle is auto adjustable through the imported servo motor between 45° to 157.5° Imported control system can accomplish cutting optimization.Several profile processing dimensions can be input in one time andmake continuous cutting.The processing dimension can be directly input, the cutting length can be changed without returning the reference point.The airproof device under the worktable has wonderful crumbs- clearing effect.The following saw cover keeps it working in the clean environment.The profile is clamped by two cylinders in every head, and kept the cutting

Contact Now

1, automatic feeding table can be continuously automatic clamping two profiles for feeding;2, the moving part adopts high precision straight guide rail pair, smooth running, to ensure the machining accuracy;3, the manipulator movement adopts imported servo drive, imported high precision rack and pinion drive, to ensure the feeding accuracy;4, the cutting height of the saw blade can be adjusted, the user can set the cutting height according to the specific profile, reduce the running space of the saw blade, improve the cutting efficiency.

Contact Now

LZK-CNC-150Such as the center stile of aluminum-plastic profiles and various holes of louvers.Numerical control system control, simple operation, accurate processing and high efficiency.This machine replaces many complicated processes such as manual marking and pistol drilling, and improves the machining quality and work efficiency several times.Drilling about 600 square meters every day greatly reduces the labor intensity of workers, and the drilling spacing and speed can be adjusted at will, so it is suitable for various profiles.Power supply380V/50HzMotor power2×1.5kWOperation air pressure0

Contact Now

This gadget is a CNC machining middle for heavy aluminum profiles, appropriate for excessive pace machining of thick and skinny wall profiles.The layout goal of the complete gadget is excessive-pace and excessive- precision machining.

Contact Now

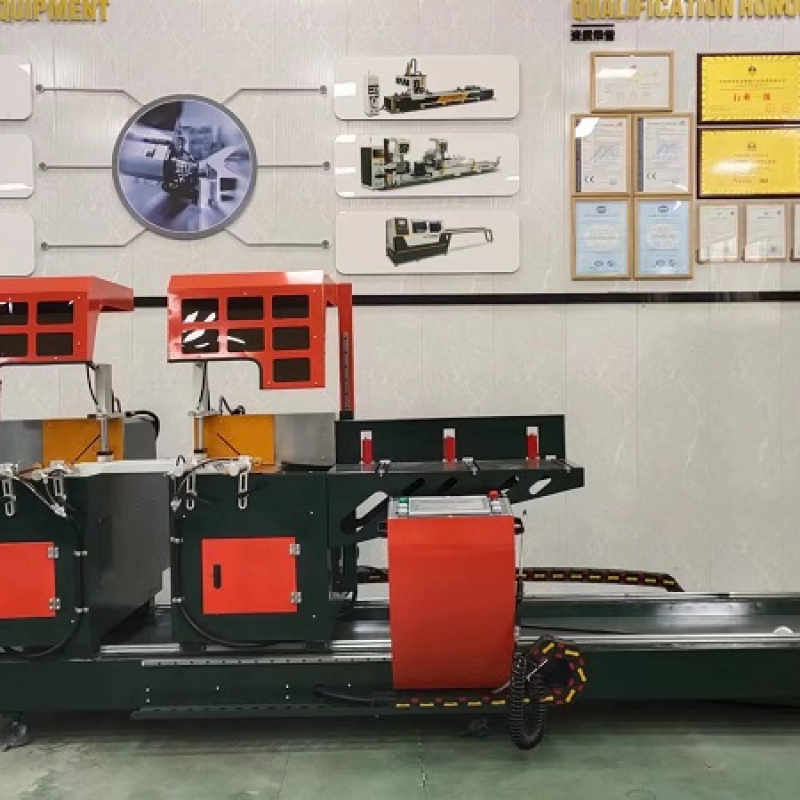

It is mainly used for cutting industrial aluminum profiles, broken bridge aluminum doors and windows, curtain wall materials, and also for cutting PVC and wood profiles.

Contact Now

Adopt Taiwan SYNTEC CNC control system. Have professional CADCAM programming software. It can transform processing G code automatically, have the function of easy operation, high efficiency and lower labor intensity.Imported guide rail, sliding block, X axis adopt high precision oblique gear and rack driving.

Contact Now

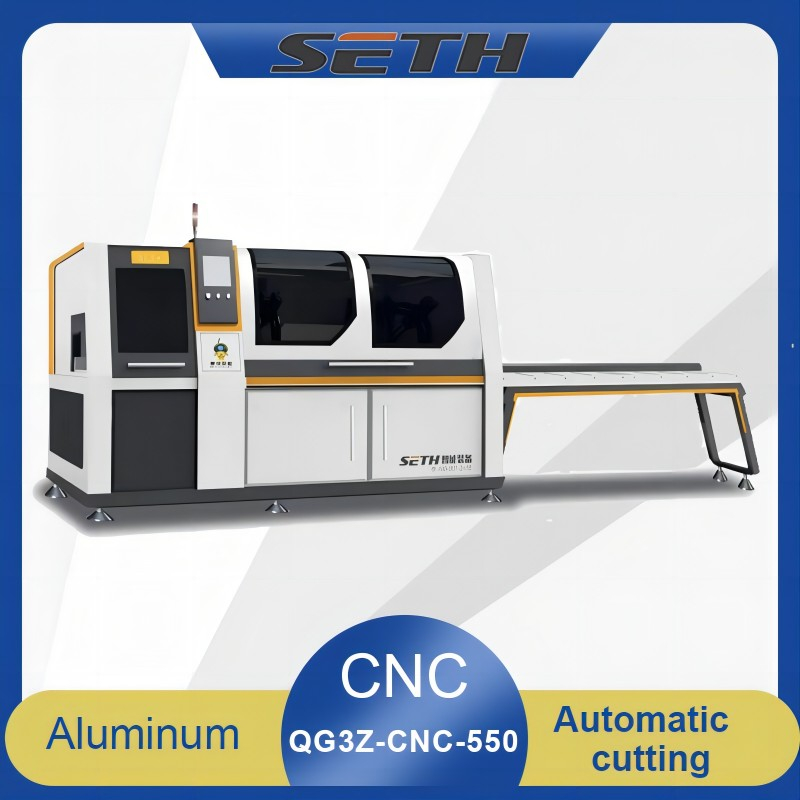

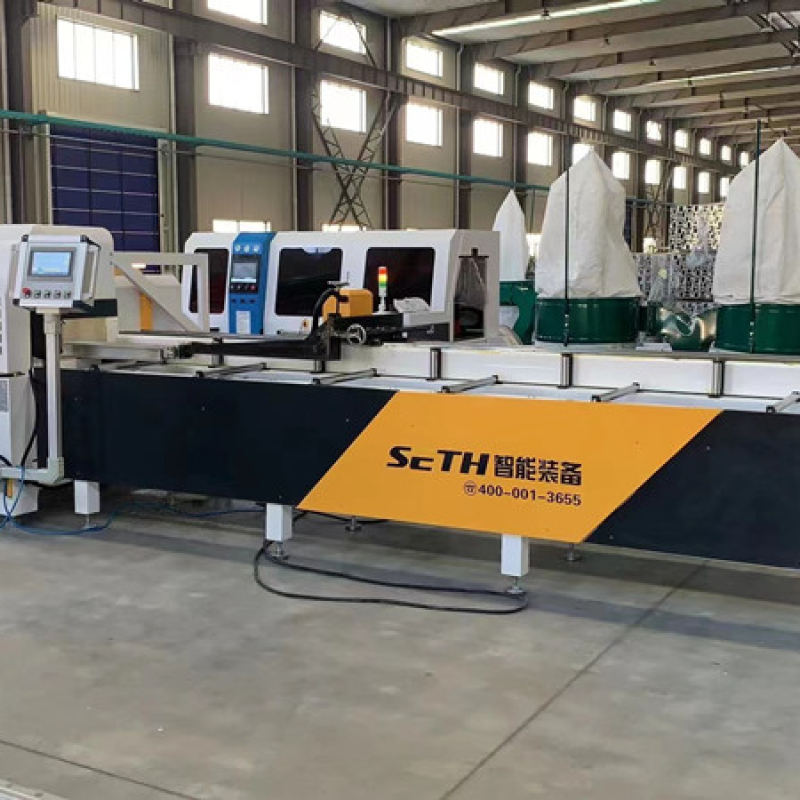

Full automatic aluminum CNC cutting machineModel:SETHQG3Z-CNC-550Power: 380v 50HzMotor power: 4kw (frequency conversion)Motor speed: 2000-4500r/min (variable frequency speed regulation)Working air pressure: 0.6 ~ 0.8MPaAutomatic feeding length: 5 ~ 3000mmCutting width: 420 mmCutting height: 150mmSawing length: No limit when selecting manualSaw blade feed speed: 0-3m/min (private feed)Saw blade specification: ø550×ø30×3.8×Z120Cutting surface flatness: ≤0.01mmCutting profile perpendicularity: ≤0.05mmCutting surface roughness: Ra12.5μmRepeatable length accuracy: ≤ 0.05mmDimensions: 11200mm×1600mm

Contact Now

1CNC machining center for heavy industrial aluminum profiles,suitable for high speed machining of thick and thin curtain wall profiles.2The design target of the whole machine is high-speed and highprecision machining.3The structure design and power ratio of the whole machine are strengthened, so that the equipment has high-strength bed and moving parts, and the service efficiency is greatly improved.4 Adopt high speed and high precision motorized spindle.X axis adopts high precision helical gear and rack, Y axis and Z axis adopt high precision ball screw drive.5 Tool design

Contact Now

With high automation, the advance and retreat of clamping and sawing are controlled by pneumatic system, which is convenient to operate, safe and reliable, and has high productivity. With automatic counting function. Continuous cutting of 6-meter angle profile can be realized only by clamping once.Automatically save the number of cut segments in case of power failure.Adopt micro spray cooling device to save the processing cost of doors and windows (alternative).Power supply380V/50HzPower supply1.5kWMotor speed2800r/minWorking pressure0.6~0.8MPaAuto feeding length2~180mmCutting widthMax.

Contact Now

Mainly used for cutting industrial aluminum profiles, broken bridge aluminum doors and windows, curtain wall materials, and also used for cutting and blanking PVC and wood profiles.The machine adopts numerical control technology, and can complete automatic positioning, cutting and blanking of profiles with different specifications and sizes.High-quality carbide saw blades for aluminum materials are selected, with an outer diameter of 500, high linear speed and high machining accuracy.Numerical control transmission adopts high standard gear rack, with high transmission precision, accurate posit

Contact Now

1.Gantry cnc machining center adopt the original imported control system, servo motor, with high-quality ball screw, linear guide and bearing and other mechanisms to ensure that the equipment has a high machining accuracy. The position of the fixture can be automatically placed.2. Double table can simultaneously carry out two pieces or two kinds of profile processing, interactive feeding, non-interference.With 12 station tool library, automatic tool change.3.

Contact Now