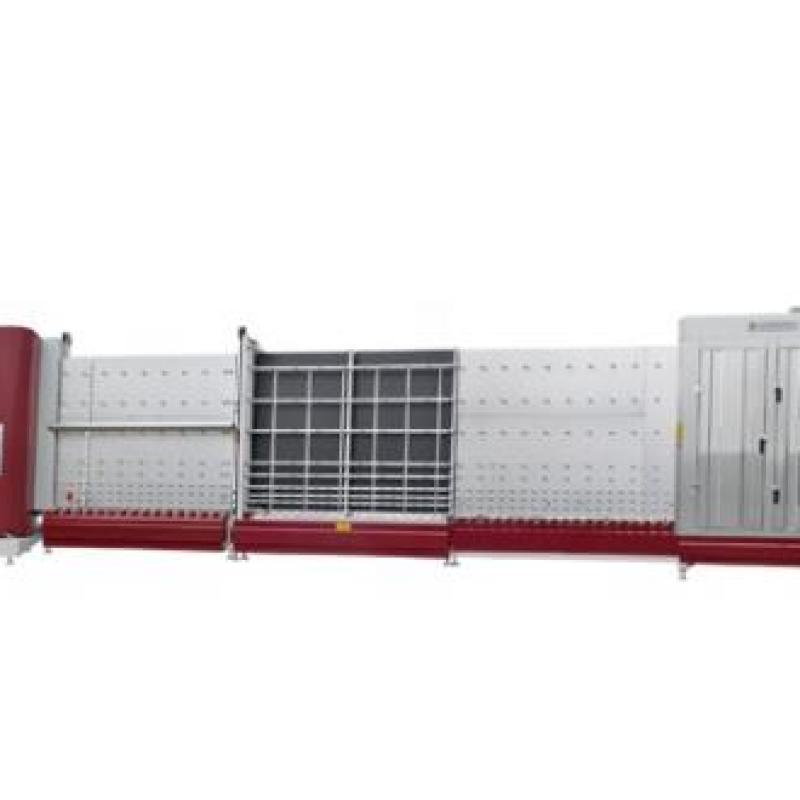

Italy Technical level of Production ,Installation and Mechanical.Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass --- two or three pieces of glass or different sizes of glass .it adjust the size of different glass by servo motor to realize high auto and more exact running.More practical and convenient design of pressing part about vacuum , pneumatic driving.

Contact Now

Feature1. used for 45 ° glass glazing bead reducing and the attitude milling and decreasing.2. one time could slicing portions of glass glazing bead.3. with degree rulers, it could processing the glazing bead in keeping with the desired length with a purpose to ensure the precision of the processing length and remove the fan frame assembly mistakes.4. four portions noticed blade make certain specific lowering, double decreasing one every surrender to mill the hook foot.5.

Contact Now

1. used for 45° glass glazing bead slicing and the angle milling and reducing.2. one time could slicing pieces of glass glazing bead.3. with measure rulers, it could processing the glazing bead in keeping with the wanted size with a view to make certain the precision of the processing size and do away with the fan body assembly blunders.4. 4 pieces noticed blade make certain unique reducing, double reducing one every give up to mill the hook foot.5.

Contact Now

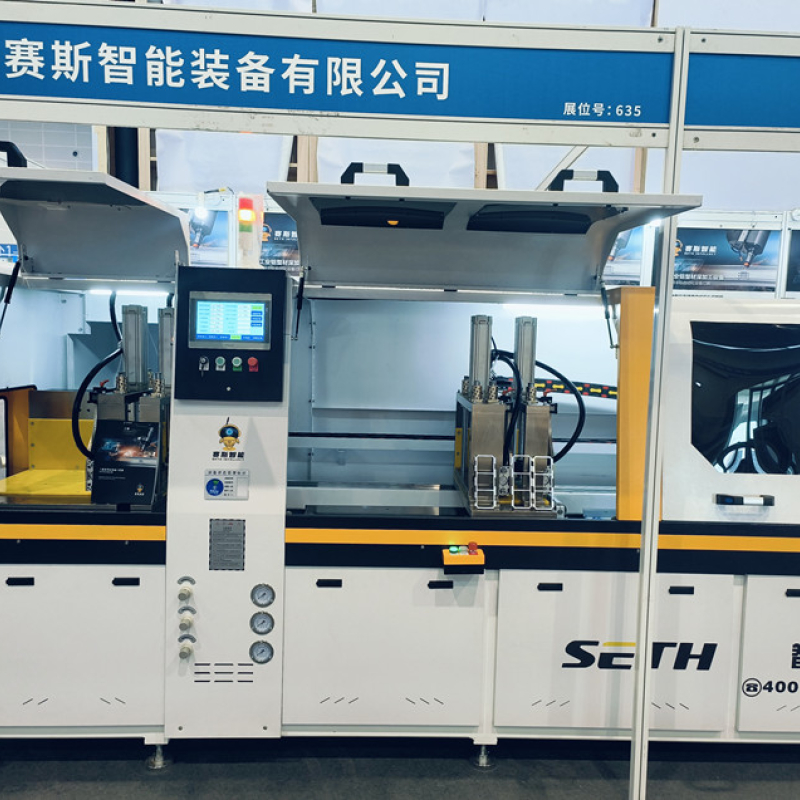

We adopt the most advanced technology for the butyl extruder machine;develop with utmost convenient for operation, which increases the production efficiency. Butyl is the key process in insulating glass production, only if the butyl sealing is perfect, you can get the perfect insulating glass. In order to get the proper connection between aluminum frame and glass, precise operation temperature is required.

Contact Now

1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

Feature1. used for 45 ° glass glazing bead lowering and the mindset milling and decreasing.2. one time ought to slicing quantities of glass glazing bead.3. with diploma rulers, it is able to processing the glazing bead in step with the favored period a good way to make sure the precision of the processing period and eliminate the fan body meeting mistakes.4. four portions noticed blade make certain specific lowering, double decreasing one every surrender to mill the hook foot.5.

Contact Now

1. used for 45° glass glazing bead cutting and the perspective milling and lowering.2. one time ought to cutting portions of glass glazing bead.3. with degree rulers, it can processing the glazing bead consistent with the desired length as a way to ensure the precision of the processing length and cast off the fan frame meeting blunders.4. four portions observed blade ensure specific lowering, double lowering one each surrender to mill the hook foot.5.

Contact Now

Feature1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

LJLY-CNC-350It is suitable for 90° precision cutting process of aluminum alloy glass wire pressing profile, and is suitable for mass continuous production.Bluetooth transmission is adopted, which is accurate and does not need secondary modification.Equipped with tool detection system to improve service life.Equipped with wireless hand-held transmission system, automatic material reduction function.The standard coding function is convenient for customers to use the material type without making mistakes, thus improving the utiliza

Contact Now

Wide Range of Use Aluminum spacer bending for insualting glass processing . Main Introduction 1. French Schneider PLC, man-machine interface, simple operation.2. French Schneider low-voltage appliances .3. Enter digital aluminum frame size.4. Aluminum strip automatic docking.5. Servo control feeding .6. Aluminum strip automatic welding function, aluminum strip welding mouth automatic avoiding7. Bend the outer is made by stainless steel guard plate.Support continuous bending of different shapes, large size

Contact Now

1, automatic feeding table can be continuously automatic clamping two profiles for feeding;2, the moving part adopts high precision straight guide rail pair, smooth running, to ensure the machining accuracy;3, the manipulator movement adopts imported servo drive, imported high precision rack and pinion drive, to ensure the feeding accuracy;4, the cutting height of the saw blade can be adjusted, the user can set the cutting height according to the specific profile, reduce the running space of the saw blade, improve the cutting efficiency.

Contact Now

With high automation, the advance and retreat of clamping and sawing are controlled by pneumatic system, which is convenient to operate, safe and reliable, and has high productivity. With automatic counting function. Continuous cutting of 6-meter angle profile can be realized only by clamping once.Automatically save the number of cut segments in case of power failure.Adopt micro spray cooling device to save the processing cost of doors and windows (alternative).Power supply380V/50HzPower supply1.5kWMotor speed2800r/minWorking pressure0.6~0.8MPaAuto feeding length2~180mmCutting widthMax.

Contact Now

Power supply380V/50HzPower supply1.5kW Motor speed2800r/minWorking pressure0.6~0.8MPaAuto feeding length2~180mmCutting widthMax. 120mmCutting heightMax. 220mmCutting lengthCutting angle90°Feeding speed0~3m/minSaw blade specificationФ450×3.8×Ф30 Z=120Overall dimension5670×1770×1840mmweight450kgs

Contact Now

Feature1.Used for mullion cutting when PVC window adopt the welding technology.2. 2 saw blades are settled as 90° so that can realize two V shape cutting by one time clamping. High precision and efficiency3. Patent technology to prevent collapse cutting precede.4. Easily adjustable depth, and adjustable stable feeding speed.5. Automatic crossing cutting two mullion end in one time. Save profile cost and improve efficiency. Support arm ensure cutting precision.6. Special clamping device ensure safety operation.

Contact Now

Window door making machine cnc double head cutting off sawFeatures:1. Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.2. Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function.3. High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.4. Supports multiple data import modes:Internet, LAN, U disk, Blu

Contact Now

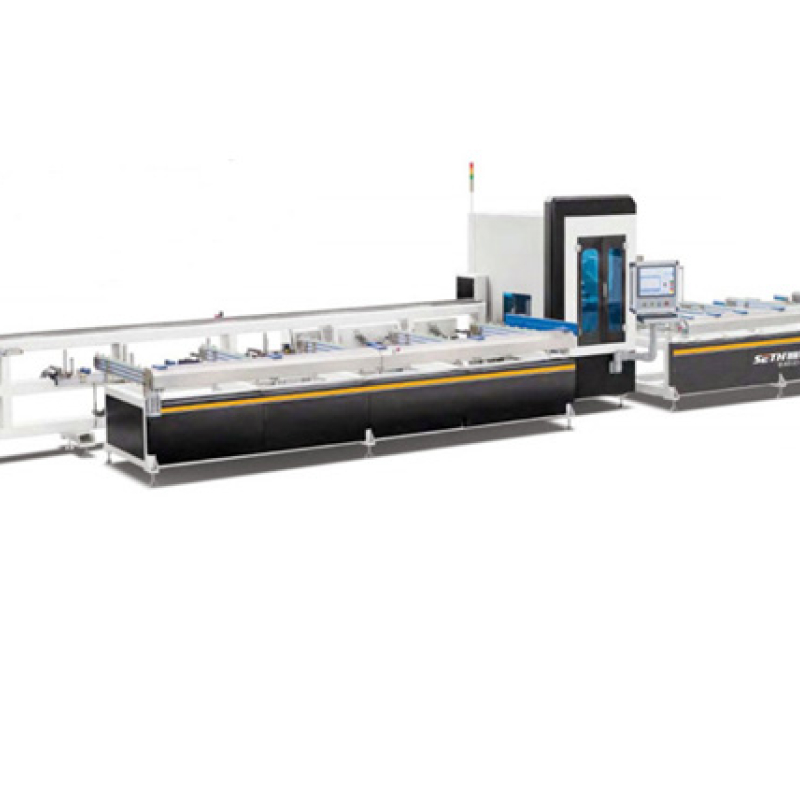

Adopt Taiwan SYNTEC CNC control system. Have professional CADCAM programming software. It can transform processing G code automatically, have the function of easy operation, high efficiency and lower labor intensity.Imported guide rail, sliding block, X axis adopt high precision oblique gear and rack driving.

Contact Now

Gadget benefits:● used for cleansing welding corners of plastic doors and home windows.● two axis cnc system.● servo drive machine, numerical manipulate device, solenoid valve, triplet and different important additives are imported well-known logo products, reliable overall performance, long carrier life.● specific inner positioning, to make sure the accuracy of the door and window weld cleansing.● can keep a spread of specs of the processing procedures.● Can realize the arc difference and oblique difference, can ideally meet the needs of all kinds of section profiles to make high-quality door

Contact Now

☆ Mainly used for cutting industrial aluminum profiles, aluminum doors and Windows, curtain wall materials, also can be used for PVC and woodCutting and blanking of profiles.☆ The machine adopts numerical control technology and can complete automatic positioning cutting of different sizes of profiles.☆ Selected high-quality aluminum carbide saw blade, outer diameter up to 500, high wire speed, high processing accuracy.☆ CNC transmission adopts high standard rack and pinion, high transmission accuracy, accurate positioning, stable work.☆ High precision spindle ensures stable rotation of saw bla

Contact Now

1. Used for welding colorful profiles, and can clean welding slag in one time, without showing the bottom color.2. Co-extrusion tool adopts aluminum alloy material, precisely proceed with high-frequency quenching.3. Equipped with automatic blowing system, can improve work efficiency.4. PLC control, pneumatic drive, simple operation, stable capability.5. Weld three-point, two point, single point, transom, cross -transom and special angle.

Contact Now

LXFG2-270*115It is suitable for copying all kinds of holes, tenons and grooves, running water troughs, etc.

Contact Now

Feature1. Used for milling all varieties of water slots and air strain stability grooves,2. Clamping one time to complete axis water slot processing3. With 2 milling heads to satisfy the one-of-a-kind necessities of the processing profile.4. The duration of milling water slot inside 60mm is adjustable and its utilization variety is wide.5.

Contact Now

Features: 1. Adopted imported CNC system, It can achieve various profile automatic cutting off in right size. 2. Imported Ball Screw control head's motion, and the two saw heads are adjustable , 3. Several profile processing dimensions can be input in one time and make continuous cutting 4. Imported high hardness diamond saw blade give accurate proc

Contact Now

Equipment advantages:● Used for cleaning welding corners of plastic doors and Windows.● Two axis CNC system.● Servo drive system, NUMERICAL control system, solenoid valve, triplet and other main components are imported famous brand products, reliable performance, long service life.● Unique internal positioning, to ensure the accuracy of the door and window weld cleaning.● Can store a variety of specifications of the processing procedures.● Can realize the arc difference and oblique difference, can ideally meet the needs of all kinds of section profiles to make high-quality doors and Windows.●

Contact Now

LXDQZ-ZD-250It is suitable for forming tenons and step surfaces of various profiles, and is a special and efficient equipment for the production of doors and windows curtain walls.The machine has the advantages of fixed profiles and moving tools, andcan realize multi-quantity and multi-batch molding of long profiles.Six sets of combined cutters can be combined into any size according to users' needs, and two sets of cutters can be adjusted within 180°.The required tenon size can be milled on the profile end face by one- time cutting.

Contact Now