LMB-SZ-120ZIt is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

1.It is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

LMB-SZ-120ZIt is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

² power:380V50Hz² Input power:2.2KW² Rated oil pump pressure:20Mpa² nominal pressure:40KN² Punching stroke:30MM² capacity of tank:30L² Oil pump dimension:6寸² Overall dimension:1000*1100*1600mm(L*W*H)weight:650Kg

Contact Now

● Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.● Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.● High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.● Supports multiple data import modes:Internet, LAN, U disk, Bluetooth, manual input, etc.

Contact Now

LXD-200AIt's miles appropriate for forming various give up grooves of aluminum profiles.Excessive-precision spindle ensures machining accuracy.Computerized feeding, low exertions intensity.The workbench can be adjusted up and down, making it handy to regulate the knife.Linear bearing ok inematic pair is used for slicing device feeding, which makes the running overall performance solid.Power supply380V/50HzRating power2.2kWMilling cutter rotary speed2800r/minAir consumption80L/minProfile height30~120mmProfile width20~120mmOverall dimension8500×740×1280mmWeightAbout 200kg

Contact Now

LJDX-BP-250*5It is suitable for milling the end face of aluminum profile, so as to meet the matching between center stile and frame material.

Contact Now

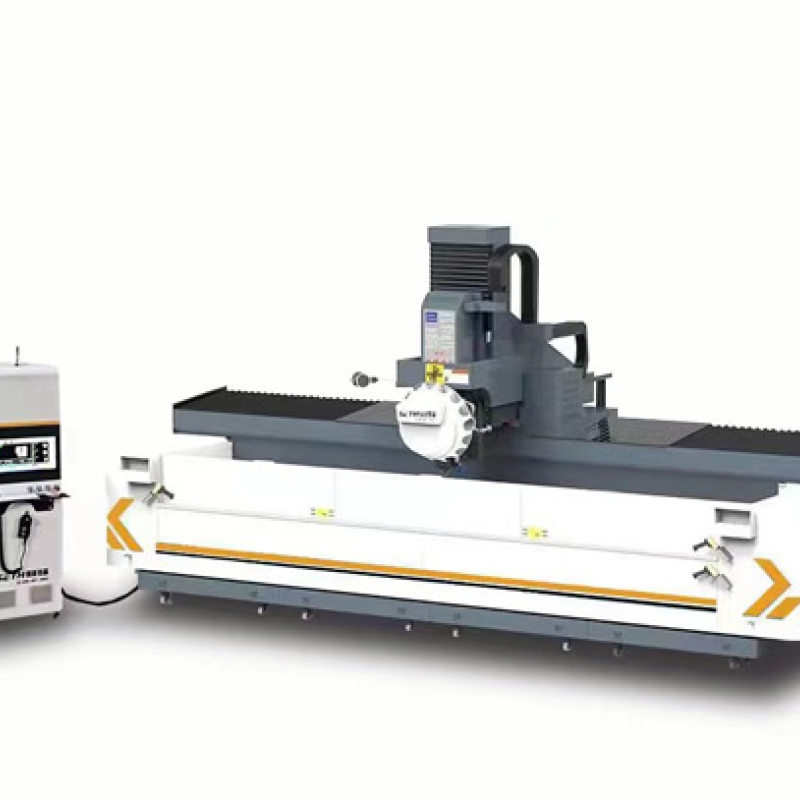

This machine is a CNC machining center for heavy aluminum profiles, suitable for high speed machining of thick and thin wall profiles.The design target of the whole machine is high-speed and high- precision machining.

Contact Now

1.It is suitable for sawing and milling the tenons and step surfaces of the castellated profiles in aluminum doors and windows.

Contact Now

LZZ6G-13It is suitable for drilling aluminum alloy doors, windows and curtain wall profiles, especially for long materials and mass production.The section is less than 200*200mm, and the processing length can reach 6000mm.Equipped with six sets of drilling heads to meet the requirement of simultaneous processing of multiple groups of holes.The display screen displays machining data in real time, which is intuitive and clear, and effectively reduces human error.The feeding adopts air c

Contact Now

LXD-200AIt's miles suitable for forming diverse surrender grooves of aluminum profiles.Excessive-precision spindle guarantees machining accuracy.Computerized feeding, low labor intensityThe workbench may be adjusted up and down, making it reachable to alter the knife.Linear bearing adequate inematic pair is used for reducing tool feeding, which makes the going for walks usual overall performance solid.Power supply380V/50HzRating power2.2kWMilling cutter rotary speed2800r/minAir consumption80L/minProfile height30~120mmProfile width20~120mmOverall dimension8500×740×1280mmWeightAbout 200kg

Contact Now

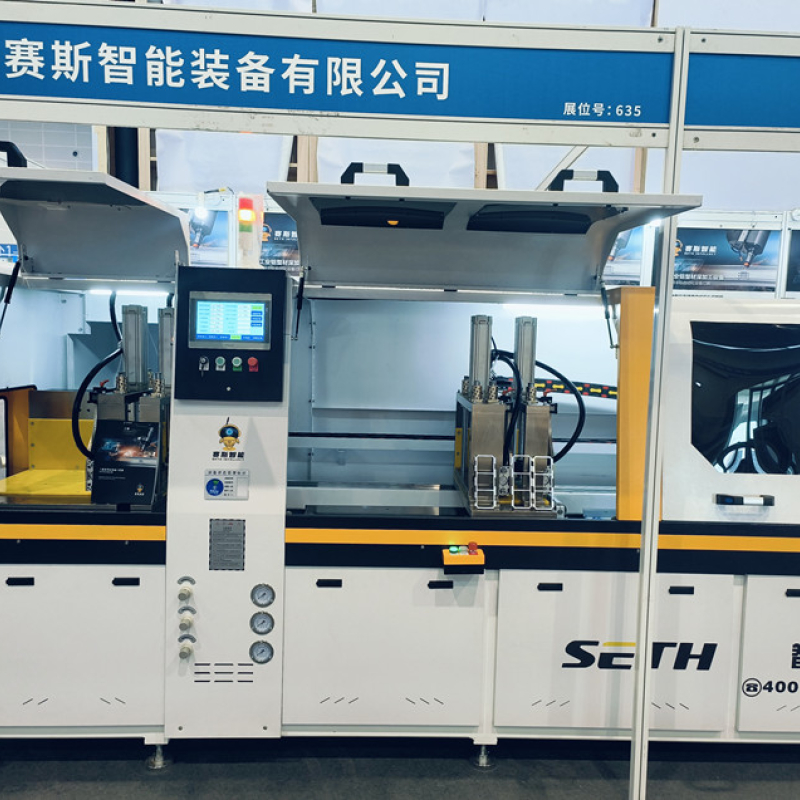

1.This machine is designed for processing round holes, slots, keyhole etc on aluminum profile, window-door and curtain wall industry, it is also suitable for processing milling, chamfering,engraving plane surface and other procedure.2. Main spindle adopt air-cooling electric main axis, 3kW power, 0~18000r/min , have the function of high precision, high safety and high reliable.3.Adopt Taiwan SYNTEC CNC control system. Have professional CAD CAM programming software.

Contact Now

LJVW-60It is suitable for cutting 90°V-shaped grooves of aluminum-plastic profiles.Automatic central positioning device for easy operation.Pneumatic transmission is easy to operate.The mechanism design of the whole machine is reasonable and the operation is safe and convenient.Power supply380V/50HzRating power2.2kWMotor rotary speed2800r/minCutting Width120mmCutting height20~60mmCutting length300~1700mmOverall dimension1350×600×1350mmWeightAbout 200kg

Contact Now

LJLY-CNC-350It is suitable for 90° precision cutting process of aluminum alloy glass wire pressing profile, and is suitable for mass continuous production.Bluetooth transmission is adopted, which is accurate and does not need secondary modification.Equipped with tool detection system to improve service life.Equipped with wireless hand-held transmission system, automatic material reduction function.The standard coding function is convenient for customers to use the material type without making mistakes, thus improving the utiliza

Contact Now

3 axis CNC Machining Center for Aluminum ProfileModel:DSK-CNC-3500Equipment features:● This model for the system door and window intelligent connection model, support ERP MES management software door and window software docking, to achieve the integration of production and marketing control to improve production efficiency.● Scanning sawing two-dimensional code system automatically generates round holes, slot holes, keyholes, special-shaped holes, milling, chamfering, and other processes without manual participation to reduce manual labor intensity and improve the qualified rat

Contact Now

End milling machine for aluminum window profileFeatrure:(1)Milling the aluminum mullion profile to connect the mullion profile and frame profile.(2)Can mill many profile in one time with high productivity.(3)Milling Knives can be adjusted up/down and left/right to meet different type of profile.(4)Milling knives are adjustable for milling different profile, without special made knives(5)Large diameter of milling knives, high speed milling, good quality milling profile surface.(6)Adopted the electrical motor protect device to improve the safety.Power supply 380V/50HzTotal motor power4.4kWM

Contact Now

Wide Range of Use Aluminum spacer bending for insualting glass processing . Main Introduction 1. French Schneider PLC, man-machine interface, simple operation.2. French Schneider low-voltage appliances .3. Enter digital aluminum frame size.4. Aluminum strip automatic docking.5. Servo control feeding .6. Aluminum strip automatic welding function, aluminum strip welding mouth automatic avoiding7. Bend the outer is made by stainless steel guard plate.Support continuous bending of different shapes, large size

Contact Now

LXDQZ-ZD-250It is suitable for forming tenons and step surfaces of various profiles, and is a special and efficient equipment for the production of doors and windows curtain walls.The machine has the advantages of fixed profiles and moving tools, andcan realize multi-quantity and multi-batch molding of long profiles.Six sets of combined cutters can be combined into any size according to users' needs, and two sets of cutters can be adjusted within 180°.The required tenon size can be milled on the profile end face by one- time cutting.

Contact Now

This gadget is a CNC machining middle for heavy aluminum profiles, appropriate for excessive pace machining of thick and skinny wall profiles.The layout goal of the complete gadget is excessive-pace and excessive- precision machining.

Contact Now

☆ Mainly used for cutting industrial aluminum profiles, aluminum doors and Windows, curtain wall materials, also can be used for PVC and woodCutting and blanking of profiles.☆ The machine adopts numerical control technology and can complete automatic positioning cutting of different sizes of profiles.☆ Selected high-quality aluminum carbide saw blade, outer diameter up to 500, high wire speed, high processing accuracy.☆ CNC transmission adopts high standard rack and pinion, high transmission accuracy, accurate positioning, stable work.☆ High precision spindle ensures stable rotation of saw bla

Contact Now

Features of equipment:Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.● Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.● High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.● Supports multiple data import modes:Internet, LAN, U disk, Bluetooth, manual input, etc.

Contact Now

1CNC machining center for heavy industrial aluminum profiles,suitable for high speed machining of thick and thin curtain wall profiles.2The design target of the whole machine is high-speed and highprecision machining.3The structure design and power ratio of the whole machine are strengthened, so that the equipment has high-strength bed and moving parts, and the service efficiency is greatly improved.4 Adopt high speed and high precision motorized spindle.X axis adopts high precision helical gear and rack, Y axis and Z axis adopt high precision ball screw drive.5 Tool design

Contact Now

☆ especially used for slicing commercial aluminum profiles, aluminum doorways and domestic home windows, curtain wall substances, additionally may be used for percent and wood slicing and blanking of profiles.☆ the tool adopts numerical control technology and can complete automated positioning cutting of various sizes of profiles.☆ decided on awesome aluminum carbide saw blade, outer diameter as much as 500, high cord speed, high processing accuracy.☆ cnc transmission adopts immoderate popular rack and pinion, immoderate transmission accuracy, accurate positioning, stable artwork.☆ high precis

Contact Now

1. Use international special CNC system;2. Suitable for processing various lengths of steel, aluminum, copper metal and non-metal;3. Adopt double cantilever design structure, increase the stability and rigidity of equipment, suitable for heavy cutting, improve the machining accuracy;4. Adopt large inclined sheet metal organ cover protection;5. BT40/BT50 spindle taper hole, increase the machine rigidity, processing efficiency, precision, high strength;6.

Contact Now