1. Used for welding colourful profiles, and may easy welding slag in a single time, with out displaying the lowest color.2. Co-extrusion device adopts aluminum alloy material, exactly continue with high-frequency quenching.3. Equipped with automated blowing system, can enhance paintings efficiency.4. PLC control, pneumatic drive, easy operation, strong capability.5. Weld three-point, two point, single point, transom, cross -transom and special angle.

Contact Now

Power supply380V 50HzTotal motor power3.0KwRated pressure20MPaOperating pressure0.6~0.8MPa Air consumption5L/minFront positioning stroke170mmBackward cutter stroke120mmAdjustment range of front positioning140mmAdjustment range of angle cutter160mmHeight of machined profile160mmFuel tank capacity40LOil pump size10 “Overall dimension 870×1200×1100mmWeight 700kg

Contact Now

CNC Any Angle Cutting Saw Model:LJZA-650Suitable for cutting sections of 0-330mm, with a wide range of applications.Carbide saw blade, high processing precision and high durability.Can be used with digital display/CNC <optional> fixed-length table for high processing efficiency.Can achieve simultaneous cutting of multiple profiles <90°>CNC Single Head Any Angle Cutting Saw Machine SpecificationPower supply380V/50HzCutting Width:45° max 200mm,90° max300mmMotor speed2840r/minCutting height:max 215mmMotor Power3*1kwSaw Blade Specification::Φ600*4*Φ30 Z144Working pressure0.5~0.8MpaAir

Contact Now

1. used for welding colorful profiles, and might easy welding slag in a single time, without displaying the bottom coloration.2. co-extrusion device adopts aluminum alloy fabric, exactly continue with excessive-frequency quenching.3. prepared with computerized blowing gadget, can improve paintings efficiency.4. PLC control, pneumatic drive, simple operation, stable capability.5. Weld three-point, two point, single point, transom, cross -transom and special angle.

Contact Now

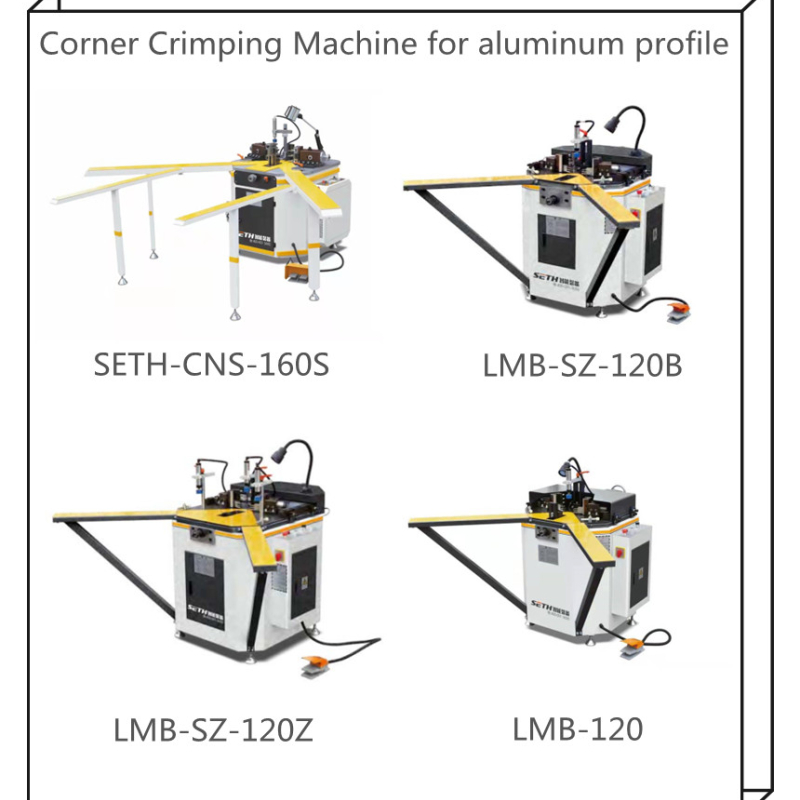

1.It is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

LMB-SZ-120ZIt is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

Power Supply380V/50HzMotor Power3.0kwMotor Speed2800r/MinWorking Pressure0.6~0.8MPaAuto Feeding Length2~580mmCutting WidthMax. 140mmCutting HeightMax. 240mmCutting LengthNo Limit If Seleting ManualCutting Angle90 DegreesFeeding SpeedInfinitely Adjustable-Speed0-3m/MinSaw Blade SpecificationΦ500×3.8×Φ30 Z=120Overall Dimension5950X1770X1840mmWeight500kg

Contact Now

LMB-SZ-120ZIt is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

1. Used for welding colorful profiles, and can clean welding slag in one time, without showing the bottom color.2. Co-extrusion tool adopts aluminum alloy material, precisely proceed with high-frequency quenching.3. Equipped with automatic blowing system, can improve work efficiency.4. PLC control, pneumatic drive, simple operation, stable capability.5. Weld three-point, two point, single point, transom, cross -transom and special angle.

Contact Now

LJZ2-CNS-500*4300The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The machine head can rotate automatically, position and clamp in two directions, and can work independently with a single machine head.Automatic opening and closing of protective cover makes operation safer.The saw blade automatically swings at an angle of 45° and 90° , and

Contact Now

1. used for 45° glass glazing bead slicing and the angle milling and reducing.2. one time could slicing pieces of glass glazing bead.3. with measure rulers, it could processing the glazing bead in keeping with the wanted size with a view to make certain the precision of the processing size and do away with the fan body assembly blunders.4. 4 pieces noticed blade make certain unique reducing, double reducing one every give up to mill the hook foot.5.

Contact Now

Power source: 380V 50HZ Total power: 15KWSaw head motor: 13KW/ 2840r/min Servo motor: 2×1KWWorking pressure: 0.6 ~ 0.8MPa sawing length: 0-6000mmCutting width: max 450mm Cutting height: max 230mmCutting Angle: 90° Feed speed: stepless speed regulation 0-3m/minSaw blade specification: ø650 × ø30 × 5.0× Z120 Repetitive cutting length accuracy: ≤ 0.05mmProfile cutting Angle tolerance: ± 3 'cutting surface roughness: Ra12.5μmDimensions: 11000× 2100× 1700 mm Weight: 3300kg

Contact Now

600mm saw blade arbitrary Angle CNC double mitre sawFeature:Mainly used for industrial aluminum profiles, aluminum doors and Windows, curtain wall material cutting.Widely used in automotive, shipbuilding, locomotive, machine tools, molds and other mechanical equipment manufacturing field of precision parts CNC processing, machine tools with high precision, high speed characteristics, can achieve high-speed cutting.The imported high-speed spindle direct connected motor is mounted with diamond saw blade.

Contact Now

LMB-120It is suitable for angle-code punching and riveting connection of aluminum doors and windows.

Contact Now

1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

Power Supply380V/50HzSaw Head Motor2*3.0km 2840r/MinWorking Pressure0.6~0.8MPaAir Supply60L/MinCutting Length380~4300mmCutting WidthMax.135mmMax.Cutting Slop45° 135X180mmCutting Angle90° 45°Feeding Speed0~3m/MinSaw Blade SpecificationΦ500X4.4X30 Z=120Overall Dimension5800X1800X1500mmWeight1750kg

Contact Now

Wide Range of Use Aluminum spacer bending for insualting glass processing . Main Introduction 1. French Schneider PLC, man-machine interface, simple operation.2. French Schneider low-voltage appliances .3. Enter digital aluminum frame size.4. Aluminum strip automatic docking.5. Servo control feeding .6. Aluminum strip automatic welding function, aluminum strip welding mouth automatic avoiding7. Bend the outer is made by stainless steel guard plate.Support continuous bending of different shapes, large size

Contact Now

1.The display screen displays machining data in real time, which is intuitive and clear, and effectively.2.The feeding adopts air cylinder and damping cylinder, which has the functions of fast forward and working forward. 3.Using high-quality control system, it can realize single machine head processing and any machine head linkage processing. 4.The machine head can be adjusted manually along the X, Y and Z axes, and is equipped with a scale, which makes the adjustment simple and convenient. 5.Z-axis is guided by linear slider, which improves the bearing capa

Contact Now

Aluminum Door Making Machine Notching Cutting SawIt's mainly used for aluminum alloy profile processing,the use of carbide saw blades,diameter up to 22'',high linear velocity,high machining accuracy.The machine with the Italian Angle display unit and original Italian delicated motor,thus processing large size range.Precise cutting angle,finish good,more suitable for aluminum alloy curtain wall,window material interface processing.Sawing(width x height) mm260*210mm (90°) ,260*146mm (45°)Blade fade rate0-3m/minWorking pressure0.6-0.8MpaMain motor power2*2.2KWSaw return

Contact Now

Numerical control transmission adopts high standard gear rack, with high transmission precision, accurate positioning and stable operation.The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The machine head can rotate automatically, position and clamp in two directions, and can work independently with a single machine head.Automatically opening and closing the protective cover,Make the operati

Contact Now

Feature1. used for 45 ° glass glazing bead reducing and the attitude milling and decreasing.2. one time could slicing portions of glass glazing bead.3. with degree rulers, it could processing the glazing bead in keeping with the desired length with a purpose to ensure the precision of the processing length and remove the fan frame assembly mistakes.4. four portions noticed blade make certain specific lowering, double decreasing one every surrender to mill the hook foot.5.

Contact Now

SHLJ-100Used for all kinds of aluminum alloy transmission box, hand lock, milling and one-time forming.Adopt double shaft combined cutting, special equipment for hand lock of transmission box.Automatic spray cooling tool, improve tool life.A clamping can be completed profiles perpendicular to each other in the two sides of the hole.The upper slot is formed by a single cutting with a professional cutter, and the length of the slot can be adjusted at will.Power supply380V/50HzTotal motor power1.5kW+2.2kWAir consumption2L/minOperating pressure0.6~0.8MPaMotor shaft diameterФ12mmNumber of mil

Contact Now

Equipment advantages:● Used for cleansing welding corners of plastic doorways and Windows.● Two axis CNC system.● Servo power system, NUMERICAL manage system, solenoid valve, triplet and different foremost additives are imported well-known logo products, dependable performance, lengthy provider life.● Unique inner positioning, to make certain the accuracy of the door and window weld cleansing.● Can store a variety of specifications of the processing procedures.● Can realize the arc difference and oblique difference, can ideally meet the needs of all kinds of section profiles to make high-quali

Contact Now