1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

Feature1.Used for mullion cutting when PVC window adopt the welding technology.2. 2 saw blades are settled as 90° so that can realize two V shape cutting by one time clamping. High precision and efficiency3. Patent technology to prevent collapse cutting precede.4. Easily adjustable depth, and adjustable stable feeding speed.5. Automatic crossing cutting two mullion end in one time. Save profile cost and improve efficiency. Support arm ensure cutting precision.6. Special clamping device ensure safety operation.

Contact Now

Feature1.Used for mullion cutting when PVC window adopt the welding technology.2. 2 saw blades are settled as 90° so that can realize two V shape cutting by one time clamping. High precision and efficiency3. Patent technology to prevent collapse cutting precede.4. Easily adjustable depth, and adjustable stable feeding speed.5. Automatic crossing cutting two mullion end in one time. Save profile cost and improve efficiency. Support arm ensure cutting precision.6. Special clamping device ensure safety operation.

Contact Now

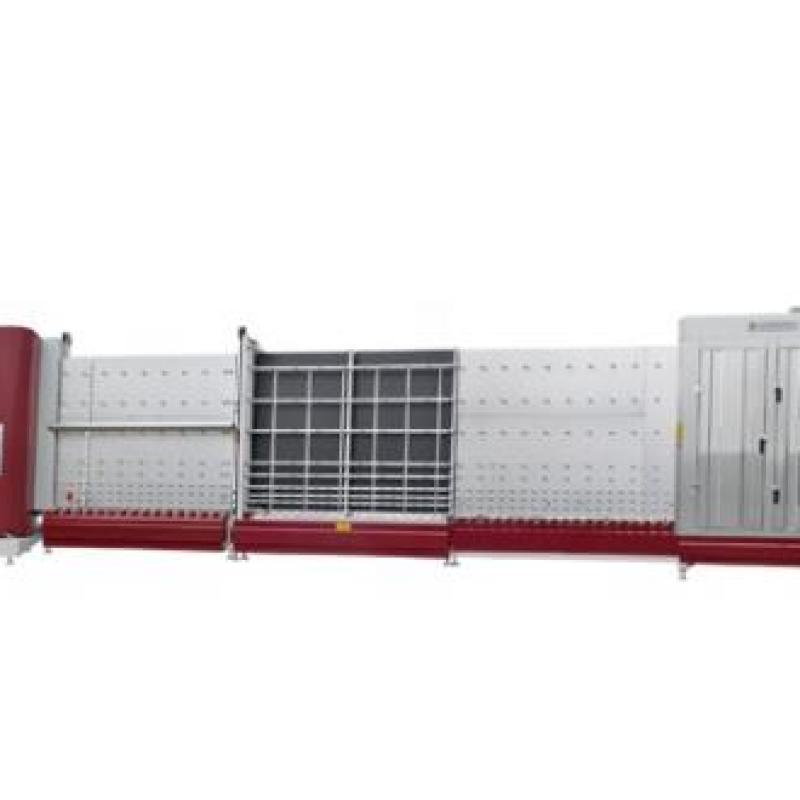

Italy Technical level of Production ,Installation and Mechanical.Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass --- two or three pieces of glass or different sizes of glass .it adjust the size of different glass by servo motor to realize high auto and more exact running.More practical and convenient design of pressing part about vacuum , pneumatic driving.

Contact Now

1).This machine, it's far our not unusualplace welding machine, in case your profile is Europe profile, it's far no problem, in case your profile is America kind profile,it wishes to make backup moulds in step with the profile pattern, so if it's far America kind profile, it wishes purchaser publish the profile pattern to us,then we make the moulds in step with the pattern.2).If you profile thickness(height) is better than 120mm, and additionally need to apply this not unusualplace welding machine, we are able to make the welding head better with a few device,however it wishes to p

Contact Now

SHLJ-100Used for all kinds of aluminum alloy transmission box, hand lock, milling and one-time forming.Adopt double shaft combined cutting, special equipment for hand lock of transmission box.Automatic spray cooling tool, improve tool life.A clamping can be completed profiles perpendicular to each other in the two sides of the hole.The upper slot is formed by a single cutting with a professional cutter, and the length of the slot can be adjusted at will.Power supply380V/50HzTotal motor power1.5kW+2.2kWAir consumption2L/minOperating pressure0.6~0.8MPaMotor shaft diameterФ12mmNumber of mil

Contact Now

Feature1.Used for mullion cutting when PVC window adopt the welding technology.2. 2 saw blades are settled as 90° so that can realize two V shape cutting by one time clamping. High precision and efficiency3. Patent technology to prevent collapse cutting precede.4. Easily adjustable depth, and adjustable stable feeding speed.5. Automatic crossing cutting two mullion end in one time. Save profile cost and improve efficiency. Support arm ensure cutting precision.6. Special clamping device ensure safety operation.

Contact Now

LJB2B-CNC-500*6000The cutting angle is auto adjustable through the imported servo motor between 45° to 157.5° Imported control system can accomplish cutting optimization.Several profile processing dimensions can be input in one time andmake continuous cutting.The processing dimension can be directly input, the cutting length can be changed without returning the reference point.The airproof device under the worktable has wonderful crumbs- clearing effect.The following saw cover keeps it working in the clean environment.The profile is clamped by two cylinders in every head, and kept the cutting

Contact Now

LJVW-60It is suitable for cutting 90°V-shaped grooves of aluminum-plastic profiles.Automatic central positioning device for easy operation.Pneumatic transmission is easy to operate.The mechanism design of the whole machine is reasonable and the operation is safe and convenient.Power supply380V/50HzRating power2.2kWMotor rotary speed2800r/minCutting Width120mmCutting height20~60mmCutting length300~1700mmOverall dimension1350×600×1350mmWeightAbout 200kg

Contact Now

LJJA-CNC-500AThe feed motion pair adopts linear motion bearing, which has small motion resistance and high precision.The feeding mechanism adopts automatic feeding system, which is stable and reliable with high efficiency.With high automation, the advance and retreat of clamping and sawing are controlled by pneumatic system, which is safe and reliable.It has automatic counting function and no cutting function of tailings.Continuous cutting of 6-meter angle profile can be realized only by clamping once.Automatically save the number of cut segments in case of power failure.Adopt micro spray cool

Contact Now

1. Used for welding colourful profiles, and may easy welding slag in a single time, with out displaying the lowest color.2. Co-extrusion device adopts aluminum alloy material, exactly continue with high-frequency quenching.3. Equipped with automated blowing system, can enhance paintings efficiency.4. PLC control, pneumatic drive, easy operation, strong capability.5. Weld three-point, two point, single point, transom, cross -transom and special angle.

Contact Now

Numerical manipulate transmission adopts excessive preferred gear rack, with excessive transmission precision, correct positioning and solid operation.The excessive-precision spindle makes the noticed blade rotate stably and efficiently improves the floor exceptional of the workpiece.Gas-liquid damping cylinder realizes uniform feed velocity law and solid movement.Adopt micro spray cooling device.The device head can rotate automatically, role and clamp in directions, and might paintings independently with a unmarried device head.Automatically opening and closing the protectiv

Contact Now

We adopt the most advanced technology for the butyl extruder machine;develop with utmost convenient for operation, which increases the production efficiency. Butyl is the key process in insulating glass production, only if the butyl sealing is perfect, you can get the perfect insulating glass. In order to get the proper connection between aluminum frame and glass, precise operation temperature is required.

Contact Now

With high automation, the advance and retreat of clamping and sawing are controlled by pneumatic system, which is convenient to operate, safe and reliable, and has high productivity. With automatic counting function. Continuous cutting of 6-meter angle profile can be realized only by clamping once.Automatically save the number of cut segments in case of power failure.Adopt micro spray cooling device to save the processing cost of doors and windows (alternative).Power supply380V/50HzPower supply1.5kWMotor speed2800r/minWorking pressure0.6~0.8MPaAuto feeding length2~180mmCutting widthMax.

Contact Now

Feature1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

Industrial Aluminium CNC Cutting SawIndustrial Aluminium CNC Cutting Saw Machine RYJ-CNC-700*13000mm☆ The servo feeding mechanism can input the dimensions of several profiles to be cut at one time,enabling continuous cutting of different lengths from 0 to 13000mm, enabling direct input of processingdimensions, and changing the sawing length without returning to the reference point.☆ This cnc cutting saw machine adopts CNC technology and can complete automatic positioning, cuttingand blanking of profiles of different sizes.☆ Use special carbide saw blades for aluminum materials, with outer

Contact Now

Numerical control transmission adopts high standard gear rack, with high transmission precision, accurate positioning and stable operation.The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The machine head can rotate automatically, position and clamp in two directions, and can work independently with a single machine head.Automatically opening and closing the protective cover,Make the operati

Contact Now

LJZ2-CNS-500*4300The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The machine head can rotate automatically, position and clamp in two directions, and can work independently with a single machine head.Automatic opening and closing of protective cover makes operation safer.The saw blade automatically swings at an angle of 45° and 90° , and

Contact Now

☆ Especially used for reducing industrial aluminum profiles, aluminum doors and home windows, curtain wall materials, also may be used for p.c and timberReducing and blanking of profiles.☆ the machine adopts numerical control era and may whole computerized positioning cutting of different sizes of profiles.☆ selected great aluminum carbide saw blade, outer diameter as much as 500, excessive wire speed, high processing accuracy.☆ cnc transmission adopts excessive popular rack and pinion, excessive transmission accuracy, correct positioning, solid work.☆ excessive precision spindle guarant

Contact Now

Adopt CNC numerical control system. Equipped with professional CAD- CAM programming software. Automatic conversion and processing of G code, simple operation, high efficiency and low labor intensity.All the kinematic pairs adopt imported guide rails and sliders, the X axis adopts high-precision helical gears and helical racks for transmission, and the Y axis and Z axis adopt high-precision ball wire shoulder transmission. The transmission is stable and the precision of the whole machine is effectively improved.The workbench is turned over 180°. -90° ~ 0° ~+90°.

Contact Now

Power supply380V/50HzSaw head motor2×3.0kW 2840r/minWorking pressure0.6~0.8MPaAir supply60L/minCutting length410~4300mmCutting widthMax. 210mmCutting heightMax. 320mmMax. cutting slope45°210×280mm 90°210×320mmCutting angle90°, 45°Feeding speed0~3m/minSaw blade specificationФ600×4.4×Ф30 Z=144 (saw blade 500/550/600mm)Overall dimension7800×1500×2040mmWeight2600kg

Contact Now

☆ Mainly used for cutting industrial aluminum profiles, aluminum doors and Windows, curtain wall materials, also can be used for PVC and woodCutting and blanking of profiles.☆ The machine adopts numerical control technology and can complete automatic positioning cutting of different sizes of profiles.☆ Selected high-quality aluminum carbide saw blade, outer diameter up to 500, high wire speed, high processing accuracy.☆ CNC transmission adopts high standard rack and pinion, high transmission accuracy, accurate positioning, stable work.☆ High precision spindle ensures stable rotation of saw bla

Contact Now

1. Used for welding colorful profiles, and can clean welding slag in one time, without showing the bottom color.2. Co-extrusion tool adopts aluminum alloy material, precisely proceed with high-frequency quenching.3. Equipped with automatic blowing system, can improve work efficiency.4. PLC control, pneumatic drive, simple operation, stable capability.5. Weld three-point, two point, single point, transom, cross -transom and special angle.

Contact Now

This machine is a CNC machining center for heavy aluminum profiles, suitable for high speed machining of thick and thin wall profiles.The design target of the whole machine is high-speed and high- precision machining.

Contact Now